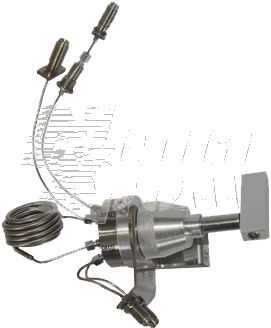

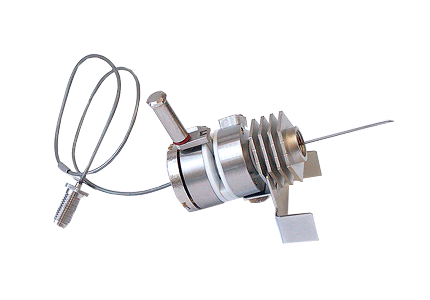

Gas sampling valve is designed for injection of gas under excess pressure into the chromatograph. Valves differ by the number of steps (4, 6, 8, 10, 12) and have to positions “Sampling” – “Analysis”. Besides sample introduction, valves can be used for switching chromatographic columns and elements of gas circuit, etc. The valve can be installed either on the side panel of chromatograph or straight into the analytical module instead of or together with chromatograph injector, in this case it is used as back flush valve or for hot input of the sample. The valve for hot input can be additionally supplied with heated pipelines.

Photo: 6 step valve

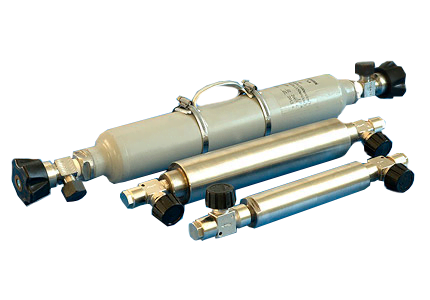

If the analyzed gas has no excess pressure, the valve can be equipped with a pump (aspirator) for sampling..

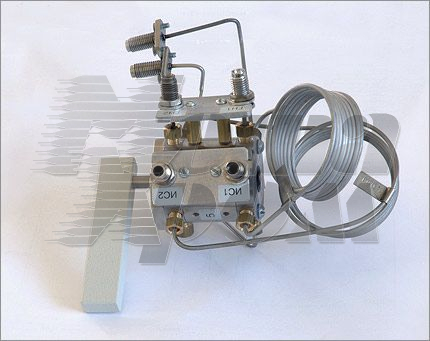

Some loop of any volume can be installed on the valve. Change of loop is done by operator when necessary. Loop volume is attested by producer by means of weight method. Loop volume is indicated on the label. The valve is supplied with a fitting that has a filter at the inlet for connection to the sampler, gas line or cylinder with calibration gas. To seal the loop and gas lines in the valve, couplings made of silicone rubber, graphite and metal are used, depending on the requirements.

Technical characteristics

- Loop volume - from 0,25 to 5,0 ml (loop volume can be increased on customer’s request up to 10 ml or reduced to 0,1 ml).

- Max valve temperature - no more than 160 °C.

- Valve line pressure - no more than 0,48 МPа.

Depending on current task and if the valve temperature is higher than 160 °C chromatograph can be supplied with sampling valves of other manufacturers, including “VICI” company (Valco Instruments).

Valco valve can be supplied with protective cover form diffusion of atmospheric air into gas mains of the valve. Cover is used during the analysis of gases with density less than 50 ppm.

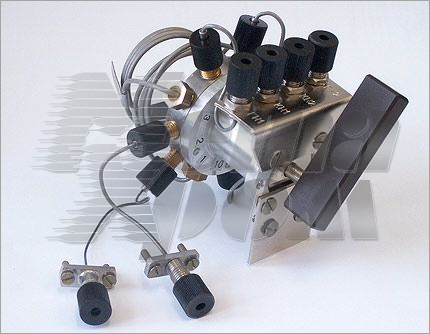

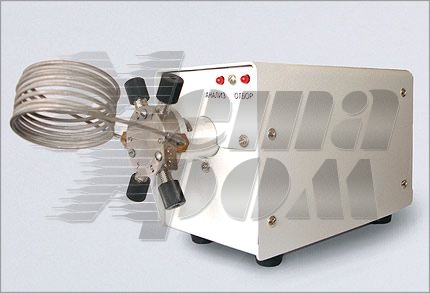

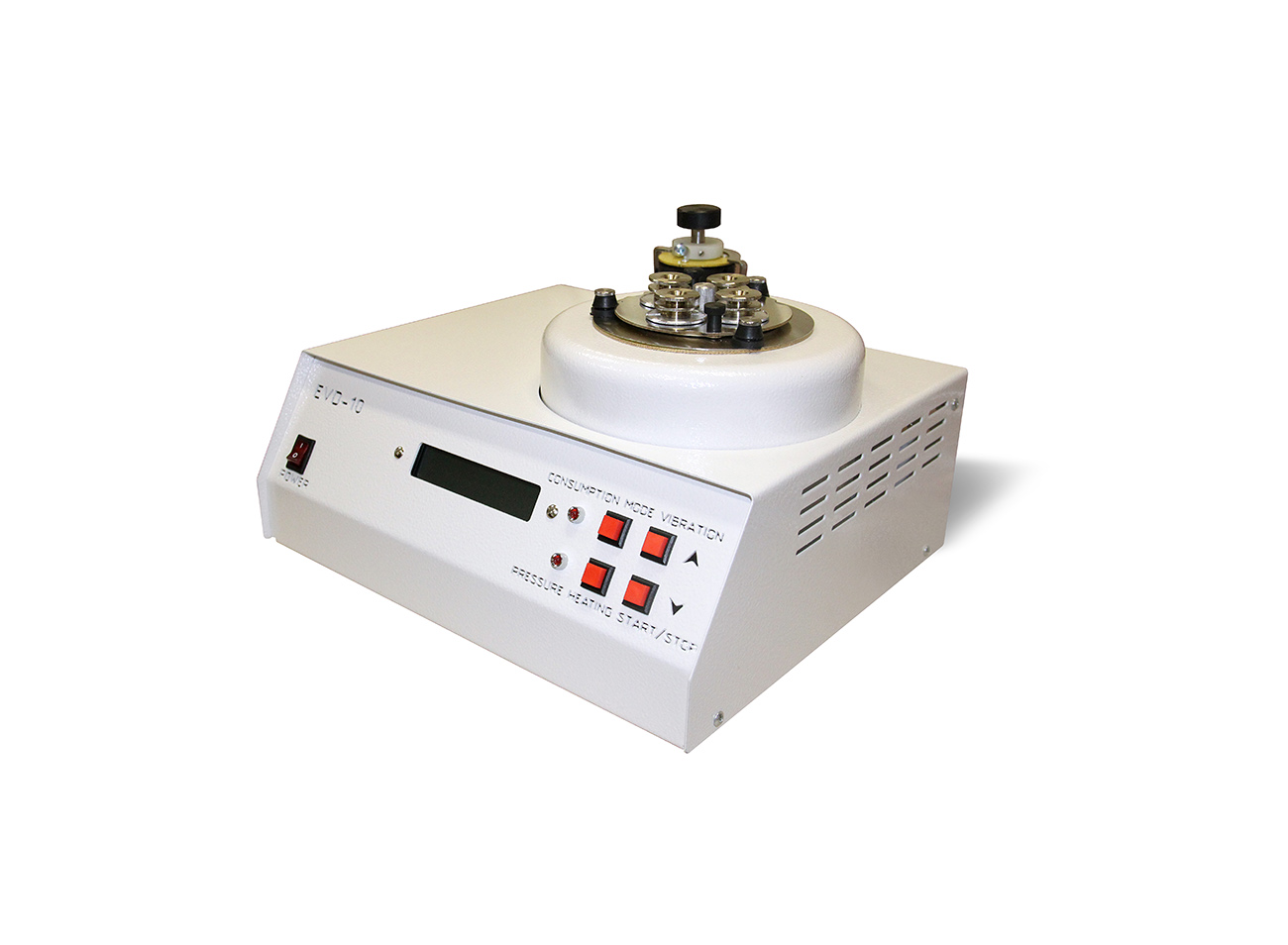

Any of the valves can be automated on customer’s request moreover automated valve can be built-in into the chromatograph or performed as a separate unit. Control of the automated valve is done by the program form chromatograph. Valve drive consists of gearmotor with position sensor located on the motor shaft.