Two-channel laboratory unit for evaluating

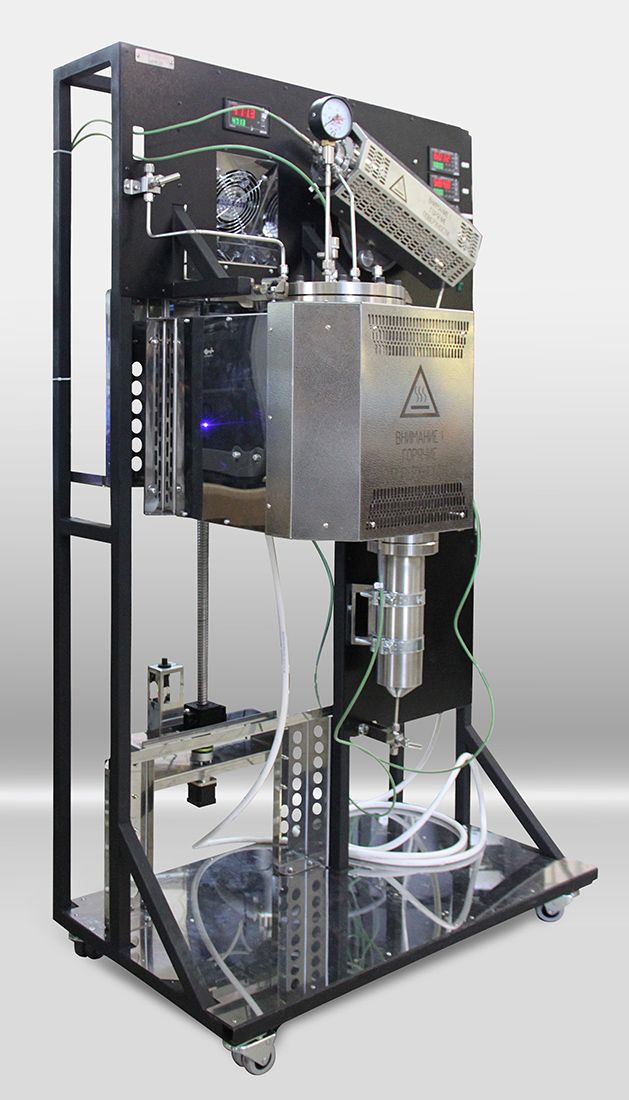

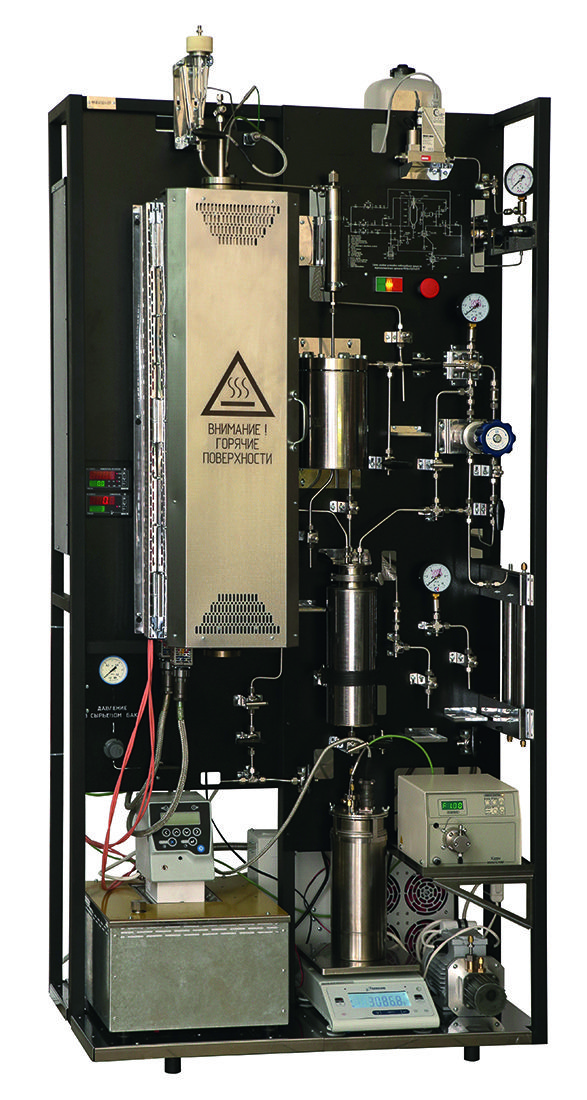

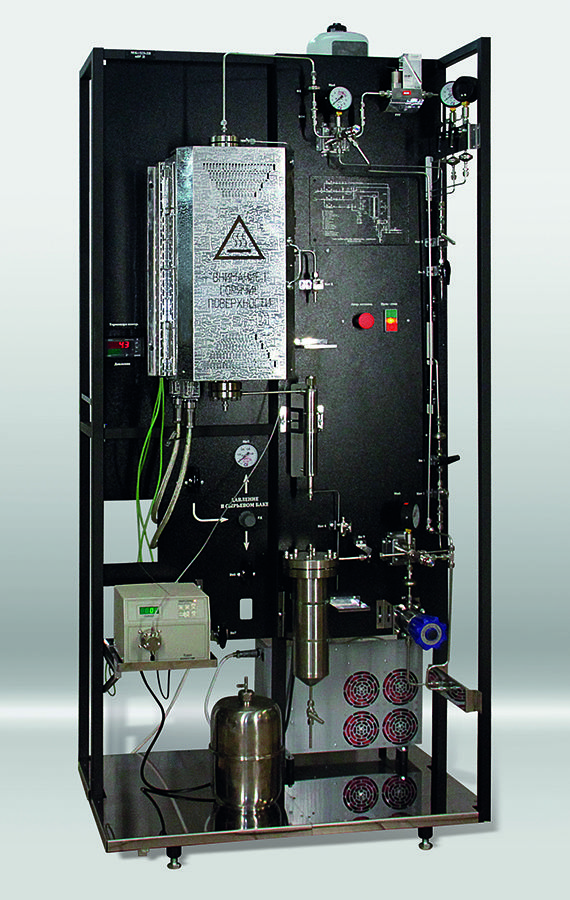

Two-channel laboratory unit for evaluating the activity of catalysts during hydrotreating and hydrocracking.

Application

A two-channel laboratory unit (hereinafter referred to as the unit) is intended for evaluating the activity of catalysts intended for hydrotreating and hydrocracking.

Specifications

Unit is a compact modular design designed to work in a dry, heated room with forced ventilation.

Plant for electrical safety meets the requirements of class 1 type N in accordance with GOST 12.2.025-76.

Operating conditions:

- Environmental temperature from +10 to +35˚С;

- Relative humidity not more than 80% at a temperature of 25˚С;

- Power supply - a three- or single-phase AC network with a voltage of 230-240 V with a frequency of 50-60 Hz.

- The average life of the appliance of plant is 5 years.

| Specifications | Value |

| Range of operaing pressures, MPa | 0,1÷10 |

| Reactor operating temperature range, 0С | 50÷600 |

| The range of flow rates of the pump forming the examine flow of raw materials, ml / min | 0,1÷10 |

| The volume of the tank for raw materials, l | More than 5 |

| Tank for raw materials operating temperature range, 0С | 30÷80 |

| Operating temperature range of high and low pressure separators, 0С | 30÷80 |

| Flow rate range H2, mm / min | 50÷3000 |

| Maximum pressure at the output of the regulator2, МПа | 10 |

| Input power no more, kW | 6 |

| Overall dimensions, mm | 800×1300×2000 |

| Mode | continuous |

Composition and structure of plant:

Plant includes:

- containers for storage and heating of raw materials;

- system of forced supply of raw materials from the tank to the inlet of the high pressure pump;

- high pressure liquid pumps;

- two four-zone ovens with reactors;

- two condensers with a coolant circulation system and a refrigerator;

- two high pressure separators with level sensor;

- two sampling systems from a high pressure separator;

- two overflow systems from the high pressure separator to the low pressure separator;

- two low-pressure separators with bubbler;

- two systems of control and automatic maintenance of pressure in the plant;

- two systems for automatic compensation of pressure drop during automatic overflow of liquid from a high-pressure separator to a low-pressure separator;

- temperature control system for high and low pressure separators;

- two automation units.

The technical characteristics of the purchased units used are given in the technical documentation for these units supplied with the unit.

Submit application

You may be interested

Our partners