- Gas chromatographs

- Gas generators

- Software

- Sample injection devices

- Service devices

- MEASURING EQUIPMENT

-

Laboratory reactor unit

- Automatic attrition tester

- Pirolysis instrument

- The laboratory unit

- Autoclave laboratory reactor

- Pilot coking unit

- Hydrotreating-reforming unit

- Bench laboratory reactor

- Automated laboratory testing unit for isobutane dehydrogenation catalyst (idc) in a pseudo-liquefied layer

- Cryoconcentration unit CCU-6

- Two-channel laboratory unit for evaluating

- Pipe thermostat

- Laboratory of catalytic unit for petrochemical industry

- Universal bench laboratory unit

- Reactor unit design

- Unit of propylene steaming

- Unit for testing activity and selectivity of fluid catalytic cracking (FCC) catalysts in fluidized bed according to ASTM D7964/D7964M-19

- The laboratory catalytic dewaxing unit

- Hydrogen station

- Bench laboratory unit for studying gas chemical processes and implementing GTL technologies according to Fischer-Tropsch.

- Automatic six-channel unit for carbon monoxide index determination

- Single-channel hydrotreating unit with up to 20 MPa working pressure

- Automation of old chromatographs

News

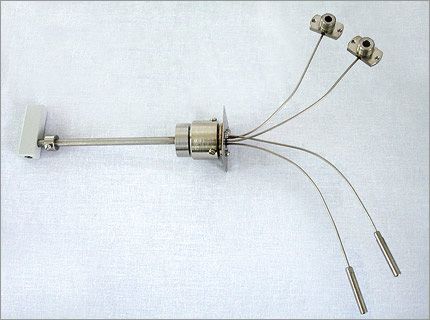

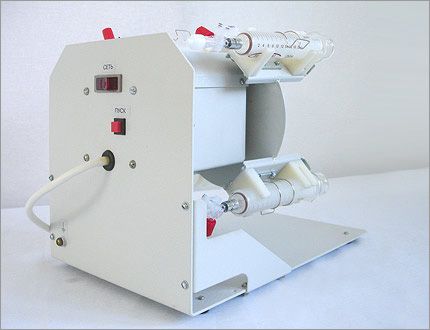

Syringe filler

During analysis of gases dissolved in transformer oil by HAS (head space analysis) method it is necessary first of all to fill the syringe with transformer oil by gas-carrier and then after obtaining equilibrium distribution of gases, dissolved in the oil, between liquid and gas phases insert gas phase into the chromatograph (blow the doses of injection valve of chromatograph). Moreover, syringe filling operations and sample injection are done without access of air. During syringe filling there is possibility to fixate the plunger on certain volume.

Photo: Syringe filler

Technical characteristics

- Syringe volume — 20 or 50 ml.

- Pressure on the outlet of syringe filling with argon line — 0,5 atm.

- Range of volume ratio of gas phase and oil (Vg/Vm) — from 0 to 1,5.

Submit application

You may be interested

News

Our partners

Medireach India Private Limited

National Research Nuclear University "MIFI"

CJSC «Rosshelf»

The Ministry of Defence of the Russian Federation

Federal space Agency («Roscosmos»)

OJSC «Salavatnefteorgsintez»

OJSC «Nizhnekamskneftekhim»

OJSC «Tatneft»

OJSC «Tobol'sk-Neftekhim»

OJSC «Caustic», Sterlitamak

Evrohim

OJSC «Nevinnomyssky Azot», Nevinnomyssk.

OJSC «Cherepovetkyi «Azot»

OJSC «Acron», Veliky Novgorod

OJSC «Halogen», Perm

OJSC «Kazanorgsintez»

OJSC «Severstal»

LLC «Kirovo-Chepetsk chemical company»

OJSC «MMC "Norilskyi Nickel»

OJSC «Nizhnekamskshina»