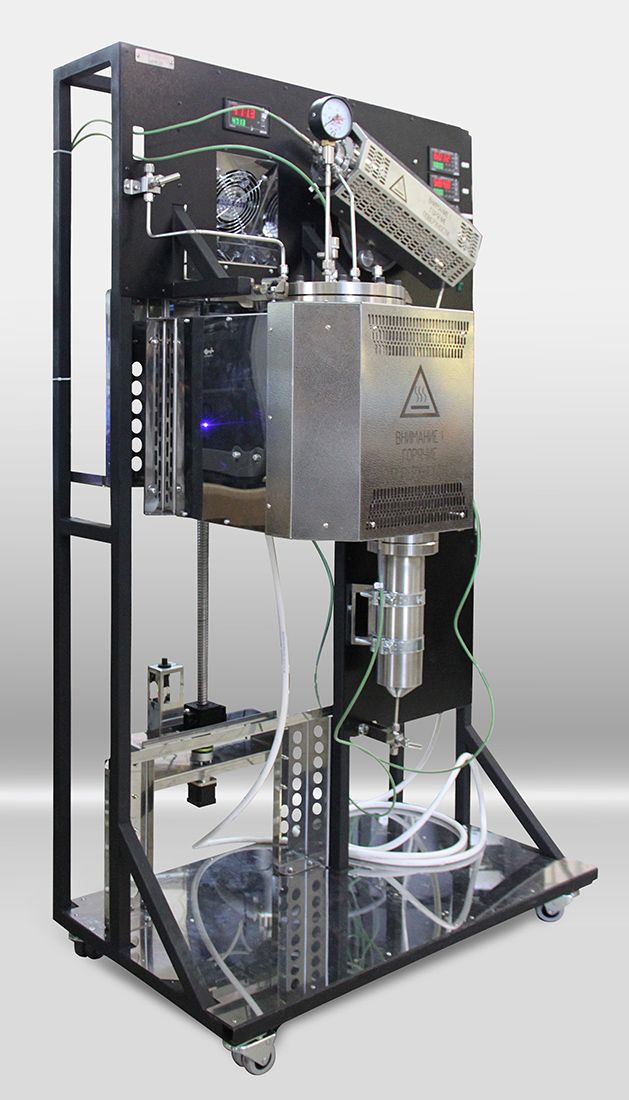

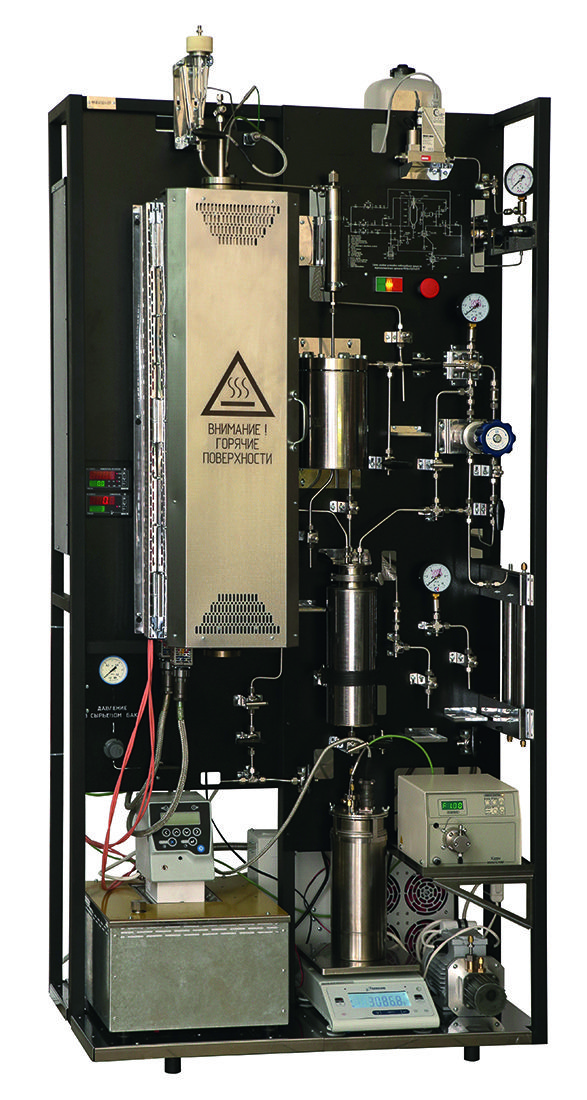

Hydrotreating-reforming unit

Purpose

The laboratory unit is designed to evaluate the activity of heterogeneous catalysts in a fixed bed reactor for the hydrotreating process.

Specifications

The unit is a rack with unit assemblies fixed to it, housed in a ventilated cabinet with a glass lockable door, a service door and easily removable side walls. The installation for electrical safety meets the requirements of class 1, type H in accordance with GOST 12.2.025-76.

Operating conditions:

- Ambient temperature from +10 до +35˚С;

- Relative air humidity not more than 80% at temperature 25˚С;

- Single-phase AC network with voltage of 220 V ± 10% and frequency of 50 Hz.

- Average service life of the unit 5 years.

| Technical characteristics of the hydrotreating and hydrogenation unit | Value |

| Reactor: pcs | 1 |

| Reactor volume, ml | 240 |

| Material | 12Х18Н10Т |

| Inner diameter, mm | 24 |

| Length, mm | 500 |

| Operating temperature range, 0С | 20÷600 |

| Working pressure range, MPa | 0÷10 |

| Removable pocket for thermocouples, mm | 600 |

| Reactor oven: pcs | 1 |

| Oven type | Winged |

| Number of temperature controlled zones, pcs | 3 |

| Length of the complete heated zone of the furnace, mm | 450 |

| Length of each of the four thermostatically controlled zones, mm | 150 |

| The length of the isothermal zone of the oven, mm | 300 |

| Power consumed by each isothermal zone, W | 800 |

| Power consumed by all three zones of the oven, W | 2400 |

| Discreteness of setting the temperature, 0С | 1 |

| Hydrogen consumption generator: pcs | 1 |

| Generator type, GFRE | Bronkhost |

| Range of supported flow rates, l / h | 0-100 |

| Inlet pressure, bar | 100 |

| Nitrogen flow generator: pcs | 1 |

| Generator type, adjustable pneumatic resistance (APR2) | Hy-Lok |

| Range of supported flow rates, l / h | 0-10 |

| Inlet pressure, bar | 0-100 |

| Raw material flow generator: pcs | 1 |

| Generator type, liquid pump | KAPPA 10 |

| Range of supported flows, ml / min | 0-10 |

| Outlet pressure, bar | 0-400 |

| Raw material volume pcs | 1 |

| Volume, l | 4 |

| Maximum pressure, atm | 4 |

| Working pressure, atm | 0,2-1 |

| Raw materials | Oil |

| Installation: pcs | 1 |

| Installation working cycle, h | 120 |

| Calculated input gas pressure H2, N2 , МПа | 10 |

| Actuation pressure of mechanical safety valves, MPa | 9,9 |

| Supply voltage | 220V 50Hz |

| Power consumption of the entire installation, no more, kW | 3 |

| Unit weight without cabinet, kg | 120 |

| Overall dimensions, mm | 1800х865х550 |

| Overall dimensions of the cabinet, mm | 2000х800х880 |

The technical characteristics of the purchased units used are given in the technical documentation for these units supplied with the unit.

Submit application

You may be interested

Our partners