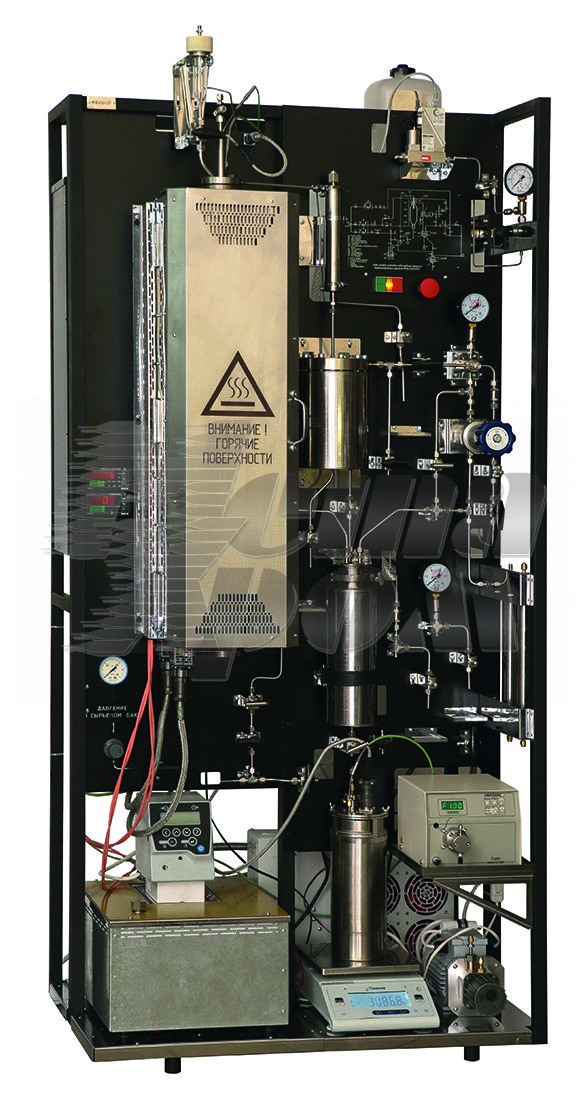

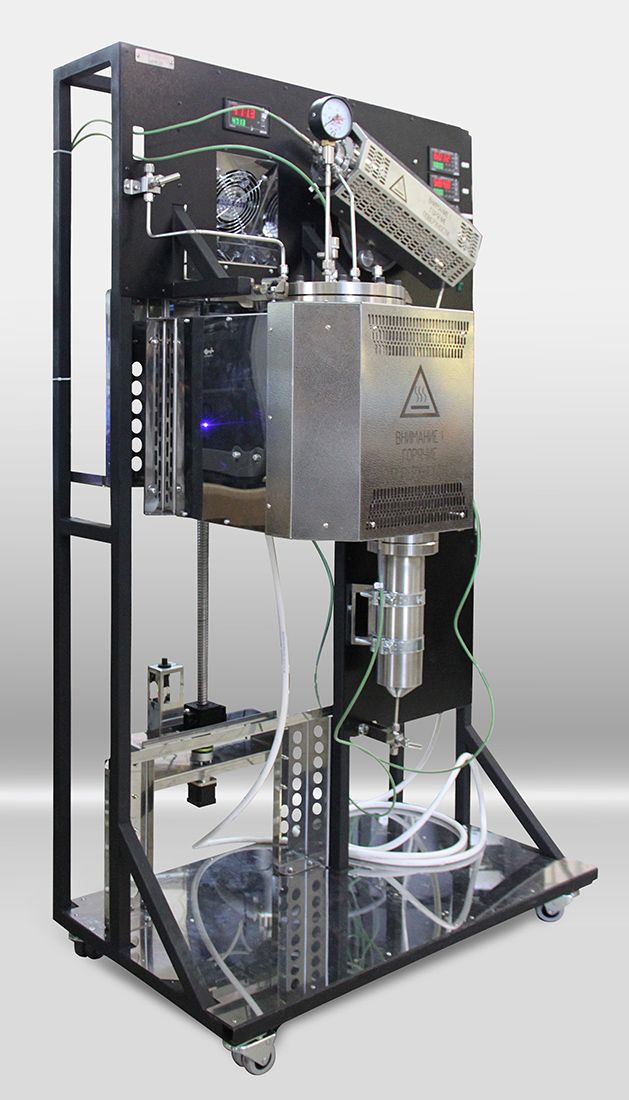

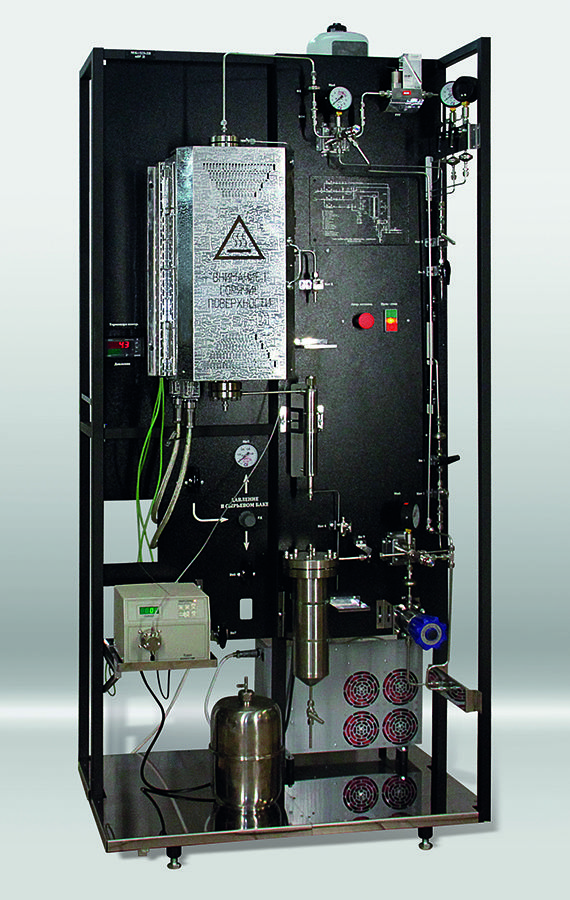

The laboratory unit

The laboratory unit for simulating thermo contact cracking process

Application

Laboratory unit for modeling the process of thermal contact cracking (TCC) of heavy oil residues (heavy fuel oil, tar and semi-tar, asphalt from high-viscosity oils deasphalting process, cracking residue, heavy gas oil, natural bitumen, etc.) with mobile solid coolant.

The Unit is a rack with the system components mounted on it, located in a ventilated cabinet with a glass lockable door for maintenance and easily removable sidewalls. 2.2. Installation for electrical safety meets the requirements of class 1 type N according to GOST 12.2.025-76.

Specifications

| Specifications | Value |

| Operating pressure range, MPa | 0÷4 |

| The range of operating temperatures of the reactor, 0С | 50÷800 |

| The inner diameter of the reactor, mm, | 31 |

| Reactor length, mm | 875 |

| Number of independent temperature control zones | 4 |

| The length of each independent isothermal zone of the oven, mm | 200 |

| The length of the full isothermal zone of the oven, mm | 800 |

| Thermocouple pocket | Available |

| Type of oven | Swing |

| Power consumption of each independent heating zone of the oven, W | 720 |

| Power consumption of all four heating zones of the oven, W | 2880 |

| Resolution of setting the temperature,0С | 1 |

| The range of flow rates of the liquid pump, ml / min | 0,1÷10 |

| Maximum pressure of a high-pressure liquid pump, not less than, MPa | 20 |

| Flow rate range N2, l / min | 0÷20 |

| Pressure in low pressure lines N2 and air, MPa | ≤0,6 |

| Range of operating temperatures of the evaporator-mixer of raw materials, 0С | 50÷500 |

| Actuation pressure of mechanical safety valves, MPa | 3 |

| The maximum pressure in the raw materials tank, MPa | 0,1 |

| Supply voltage | 230-240В 60Hz |

| Power consumption of installation no more, kW | 3,5 |

| Resolution of the temperatures and flows displayed | 0,1 |

| Unit weight without cabinet, kg | 100 |

| Overall dimensions of installation, mm | 1900х865х550 |

| Overall dimensions of the cabinet, mm | 2000х880х800 |

| Specifications of purchased units used in the installation are given in the technical documentation for these units supplied with the installation | |

| Length of gas supply pipelines, m | 10 |

| Refrigerant coolant | Antifreeze «Tosol» |

2.3. Operating conditions:

- Environmental temperature from +10 до +35˚С;

- Relative humidity not more than 80% at a temperature of 25˚С;.

- Power supply - single-phase AC network with voltage of 220 V ± 10% and frequency of 50 Hz.

The average service life of the installation is 5 years.

Submit application

You may be interested

Our partners