- Gas chromatographs

- Gas generators

- Software

- Sample injection devices

- Service devices

- MEASURING EQUIPMENT

-

Laboratory reactor unit

- Automatic attrition tester

- Pirolysis instrument

- The laboratory unit

- Autoclave laboratory reactor

- Pilot coking unit

- Hydrotreating-reforming unit

- Bench laboratory reactor

- Automated laboratory testing unit for isobutane dehydrogenation catalyst (kdi, kdi-m) in fluidizen bed layer

- Cryoconcentration unit CCU-6

- Two-channel laboratory unit for evaluating

- Pipe thermostat

- Laboratory of catalytic unit for petrochemical industry

- Universal bench laboratory unit

- Reactor unit design

- Unit of propylene steaming

- Pyrolyzer

- Device for testing friction and abrasion of catalysts "PTI-1"

- Automatic attrition tester by air jet for fluidized bed cracking catalysts by express-method

- Laboratory catalytic unit lcu-1

- High-temperature furnaces

- Pilot unit for catalytic propylene oxidation reactions

- Reactor unit for testing catalysts for hydrodewaxing and isodewaxing of base and other oils.

- Unit for petroleum pitch obtaining

- Pilot unit for delayed coking

- Unit for testing activity and selectivity of fluid catalytic cracking (FCC) catalysts in fluidized bed according to ASTM D7964/D7964M-19

- The laboratory catalytic dewaxing unit

- Hydrogen station

- Bench laboratory unit for studying gas chemical processes and implementing GTL technologies according to Fischer-Tropsch.

- Automatic six-channel unit for carbon monoxide index determination

- Single-channel hydrotreating unit with up to 20 MPa working pressure

- Automation of old chromatographs

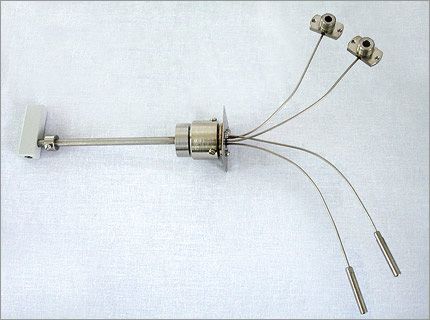

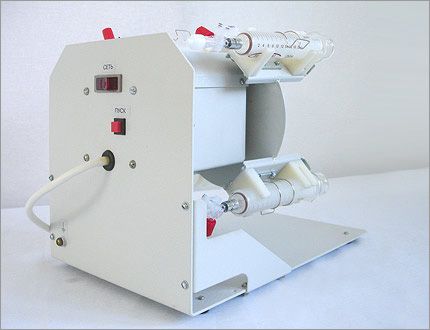

For the analysis of low concentrations of carbon monoxide (CO) and carbon dioxide (CO2) a more sensitive FID is used instead of common for this gases katharometer, at that, oxides of carbon turn into methane (CH4) with the help of reaction gas chromatography. Device that realizes conversion reaction is called methanizer, i.e. a device with special catalyst that converts CO, CO2 into methane (CH4) in hydrogen flow meanwhile the latter is gas-carrier itself or is blown together with gas-carrier into Methanizer through the tee. Methanizer ensures highly effective conversion reaction herewith detection limit of carbon oxides reaches 0,1 ppm.

Photo: Methanizer

Methanizer is a U-shaped pipe made of stainless steel with fittings on each end for packed column connection. Methanizer volume is 1 ml. Methanizer is filled with catalyst – spherochrom, treated with nitrate nickel or any other that ensures the reaction of conversion. Catalyst restoration during work is obtained by several insertions of air sample into methanizer at working temperature of about 330°C (from 3 to 5 times).

Technical characteristics

- Methanation temperature — 330 °C

- Methanation ratio — no less than 95 %

- Effective volume of Methanizer — 1 ml.