- Gas chromatographs

- Gas generators

- Software

- Sample injection devices

- Service devices

- MEASURING EQUIPMENT

-

Laboratory reactor unit

- Automatic attrition tester

- Pirolysis instrument

- The laboratory unit

- Autoclave laboratory reactor

- Pilot coking unit

- Hydrotreating-reforming unit

- Bench laboratory reactor

- Automated laboratory testing unit for isobutane dehydrogenation catalyst (kdi, kdi-m) in fluidizen bed layer

- Cryoconcentration unit CCU-6

- Two-channel laboratory unit for evaluating

- Pipe thermostat

- Laboratory of catalytic unit for petrochemical industry

- Universal bench laboratory unit

- Reactor unit design

- Unit of propylene steaming

- Pyrolyzer

- Device for testing friction and abrasion of catalysts "PTI-1"

- Automatic attrition tester by air jet for fluidized bed cracking catalysts by express-method

- Laboratory catalytic unit lcu-1

- High-temperature furnaces

- Pilot unit for catalytic propylene oxidation reactions

- Reactor unit for testing catalysts for hydrodewaxing and isodewaxing of base and other oils.

- Unit for petroleum pitch obtaining

- Pilot unit for delayed coking

- Unit for testing activity and selectivity of fluid catalytic cracking (FCC) catalysts in fluidized bed according to ASTM D7964/D7964M-19

- The laboratory catalytic dewaxing unit

- Hydrogen station

- Bench laboratory unit for studying gas chemical processes and implementing GTL technologies according to Fischer-Tropsch.

- Automatic six-channel unit for carbon monoxide index determination

- Single-channel hydrotreating unit with up to 20 MPa working pressure

- Automation of old chromatographs

News

Backflush valve

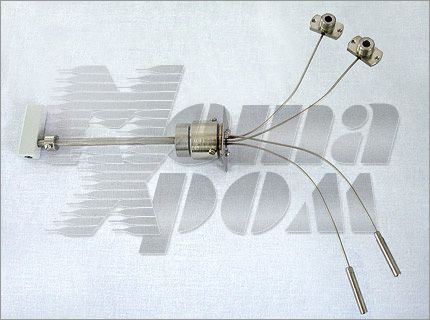

Backflush valve is a 4-step valve designed for the change of eluent flow in the packed column and for blowoff of heavy components from the entry of the column back into detector. The valve is attached to the lower panel (bottom) of the module, meanwhile taking the temperature of column thermostat. Two upper fittings (see pic.) serve for column connection, two other ones are connected to evaporator and detector.

Photo: Gas scheme of backflush valve

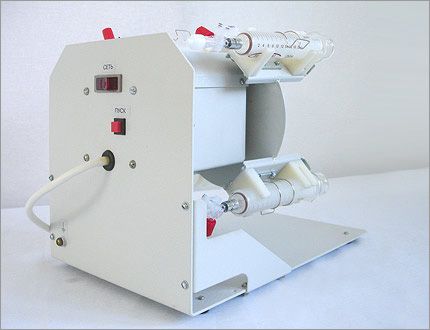

Backflush valve can be automated. Valve drive consists of gear reducer with position sensor located on motor shaft.

Submit application

You may be interested

News