- Gas chromatographs

- Gas generators

- Software

- Sample injection devices

- Service devices

- MEASURING EQUIPMENT

-

Laboratory reactor unit

- Automatic attrition tester

- Pirolysis instrument

- The laboratory unit

- Autoclave laboratory reactor

- Pilot coking unit

- Hydrotreating-reforming unit

- Bench laboratory reactor

- Automated laboratory testing unit for isobutane dehydrogenation catalyst (kdi, kdi-m) in fluidizen bed layer

- Cryoconcentration unit CCU-6

- Two-channel laboratory unit for evaluating

- Pipe thermostat

- Laboratory of catalytic unit for petrochemical industry

- Universal bench laboratory unit

- Reactor unit design

- Unit of propylene steaming

- Pyrolyzer

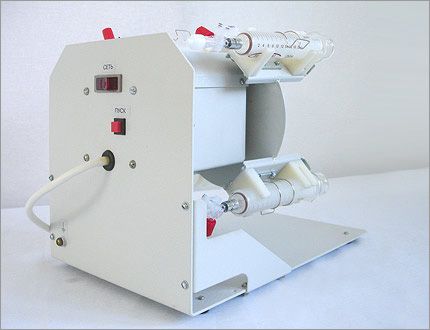

- Device for testing friction and abrasion of catalysts "PTI-1"

- Automatic attrition tester by air jet for fluidized bed cracking catalysts by express-method

- Laboratory catalytic unit lcu-1

- High-temperature furnaces

- Pilot unit for catalytic propylene oxidation reactions

- Reactor unit for testing catalysts for hydrodewaxing and isodewaxing of base and other oils.

- Unit for petroleum pitch obtaining

- Pilot unit for delayed coking

- Unit for testing activity and selectivity of fluid catalytic cracking (FCC) catalysts in fluidized bed according to ASTM D7964/D7964M-19

- The laboratory catalytic dewaxing unit

- Hydrogen station

- Bench laboratory unit for studying gas chemical processes and implementing GTL technologies according to Fischer-Tropsch.

- Automatic six-channel unit for carbon monoxide index determination

- Single-channel hydrotreating unit with up to 20 MPa working pressure

- Automation of old chromatographs

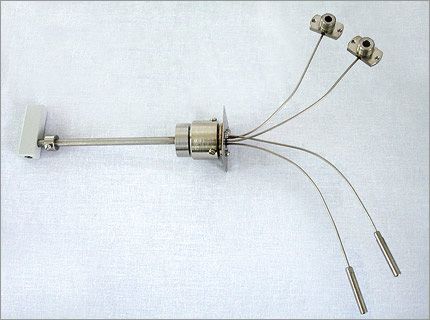

The gas flow and pressure indicator (FPI) is designed to monitor the pressure and flow rate of non-aggressive gases in the pipelines of chromatographic and other analytical equipment.

The measurement of gas flow is based on the conversion of the gas mass flow rate into an electrical signal by the calorimetric method. The measured gas flow and pressure are displayed on a digital indicator. The device has an external RS 485 interface, operating under the MODBUS RTU protocol.

Technical specifications:

- gas flow measurement range – from 1 to 750 ml/min;

- pressure measurement range from 0 to 0.4 MPa;

- gas flow measurement error – less than ± 2% in the measurement range of 100 art.ml/min; less than 3% in the measurement range of 100 ... 750 art. ml/min;

- measurement error suppression – less than ± 0.25 %;

- measured gases: Air, Nitrogen, Hydrogen, Helium, Argon, Methane;

- function of monitoring the pumped gas volume for a given period of time;

- function of monitoring changes in gas pressure for a given period of time;

- the device is powered from an external power supply +15V (220V 50Hz network adapter is included in the package).