Application

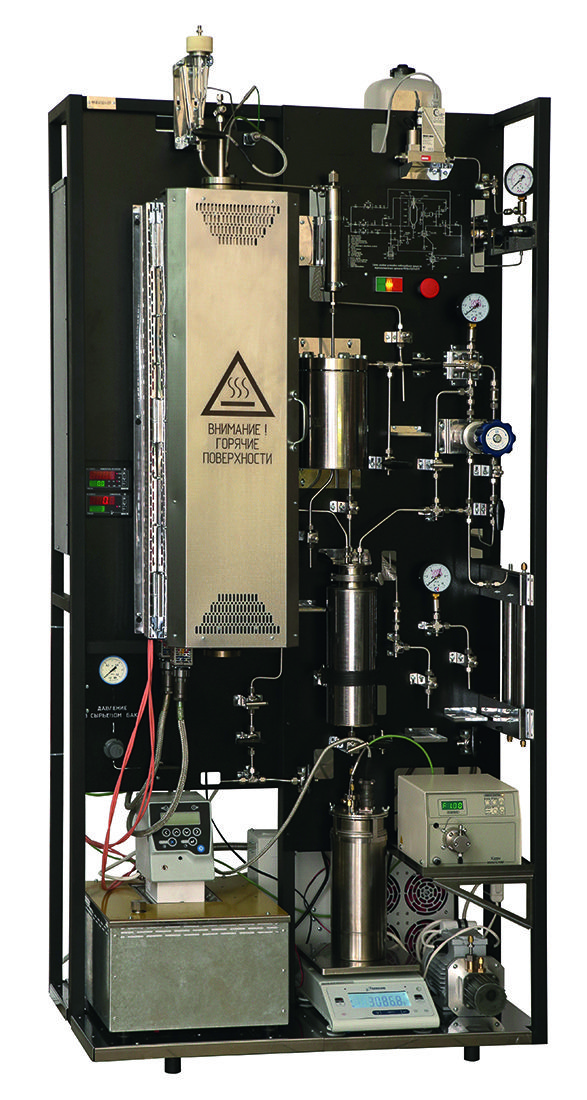

The instrument is designed to simulate and study pyrolysis processes which pass at elevated temperatures and pressures in a stainless steel reactor made in the form of a flask. The installation allows obtaining experimental data, selecting and optimizing the parameters of the technological process, testing various options for raw mixtures, determining the material balance of the process, the characteristics of the process products.

Application

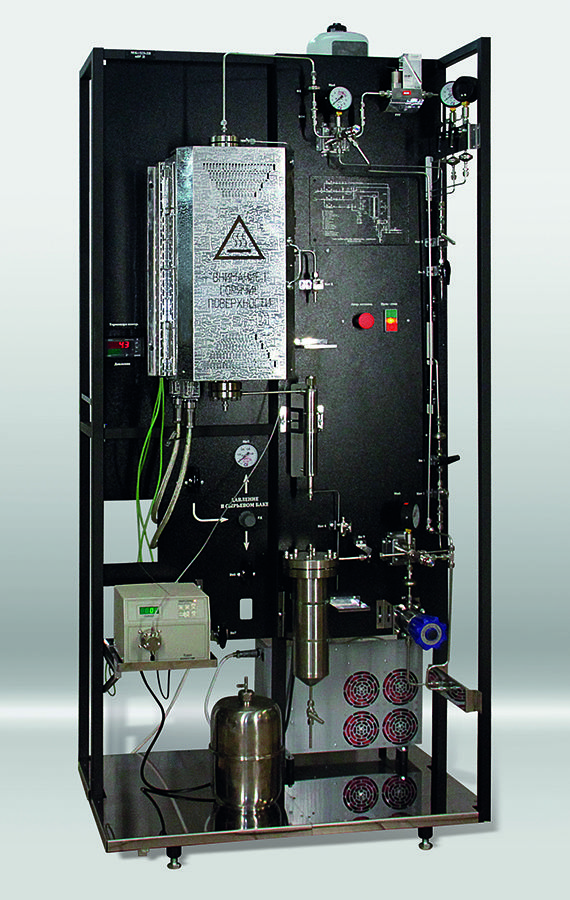

The unit is designed to simulate and study pyrolysis processes which pass at elevated temperatures and pressures. The unit allows obtain experimental data, select and optimize the parameters of the technological process, testing various options for raw mixtures, determining the material balance of the process, the characteristics of the process products.

Operating conditions

· Environmental temperature from +10 до +35 °С;

· Relative humidity not more than 80% at a temperature of 25 °C;

· Power supply - single-phase 220-240 V 50-60 Hz.

Technical characteristics:

|

Specifications |

Value |

|

Operating pressure range, MPa |

-1÷10 |

|

Volume of the flask oven with independent heating of the bottom and walls, equipped with an automatic lifting mechanism, liter |

0,1÷10 |

|

Flask oven operating temperature range, °С |

50÷650 |

|

Pyrolyzer operating temperature range, °С |

50÷1000 |

|

Temperature setting accuracy, °С |

1 |

|

Reactor material |

stainless steel |

|

Refrigerator «tube in tube» |

included |

|

Volume of 2 separators, liter |

1,2 |

|

Pressure regulator «before itself» |

included |

|

Power consumption, kW |

3,5 |

|

Overall dimensions, mm |

1600х900х580 |

|

Weight, kg |

100 |

|

Work mode |

continuous |