- Gas chromatographs

- Gas generators

- Software

- Sample injection devices

- Service devices

- MEASURING EQUIPMENT

-

Laboratory reactor unit

- Automatic attrition tester

- Pirolysis instrument

- The laboratory unit

- Autoclave laboratory reactor

- Pilot coking unit

- Hydrotreating-reforming unit

- Bench laboratory reactor

- Automated laboratory testing unit for isobutane dehydrogenation catalyst (kdi, kdi-m) in fluidizen bed layer

- Cryoconcentration unit CCU-6

- Two-channel laboratory unit for evaluating

- Pipe thermostat

- Laboratory of catalytic unit for petrochemical industry

- Universal bench laboratory unit

- Reactor unit design

- Unit of propylene steaming

- Pyrolyzer

- Device for testing friction and abrasion of catalysts "PTI-1"

- Automatic attrition tester by air jet for fluidized bed cracking catalysts by express-method

- Laboratory catalytic unit lcu-1

- High-temperature furnaces

- Pilot unit for catalytic propylene oxidation reactions

- Reactor unit for testing catalysts for hydrodewaxing and isodewaxing of base and other oils.

- Unit for petroleum pitch obtaining

- Pilot unit for delayed coking

- Unit for testing activity and selectivity of fluid catalytic cracking (FCC) catalysts in fluidized bed according to ASTM D7964/D7964M-19

- The laboratory catalytic dewaxing unit

- Hydrogen station

- Bench laboratory unit for studying gas chemical processes and implementing GTL technologies according to Fischer-Tropsch.

- Automatic six-channel unit for carbon monoxide index determination

- Single-channel hydrotreating unit with up to 20 MPa working pressure

- Automation of old chromatographs

News

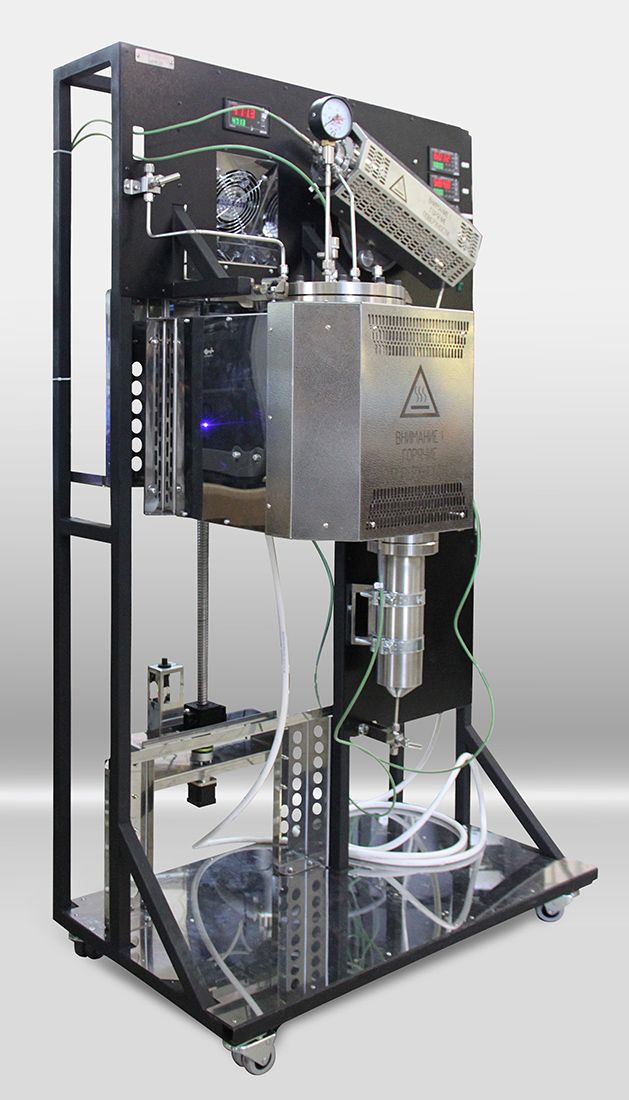

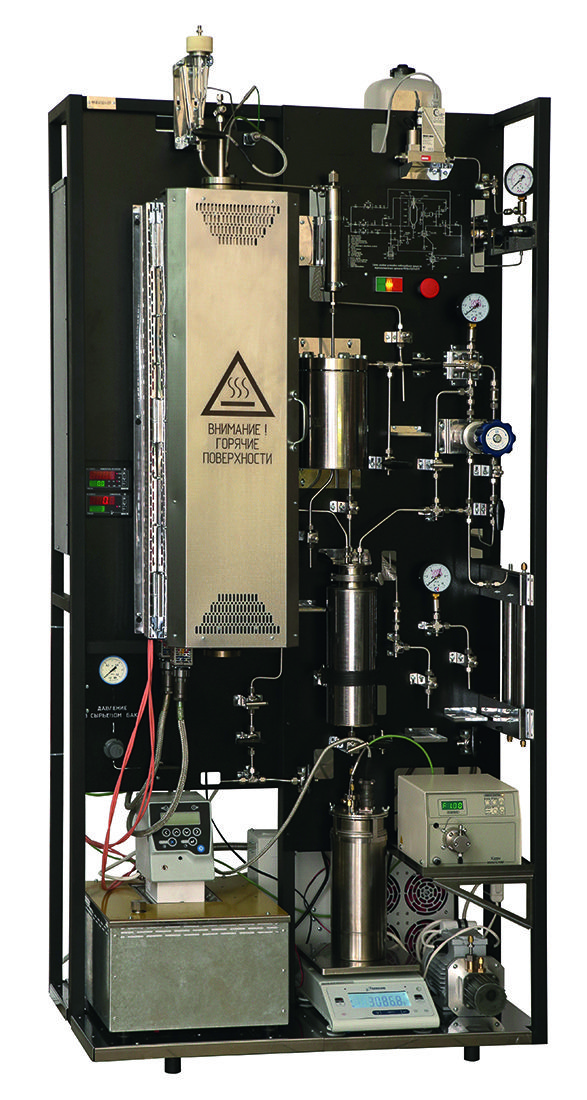

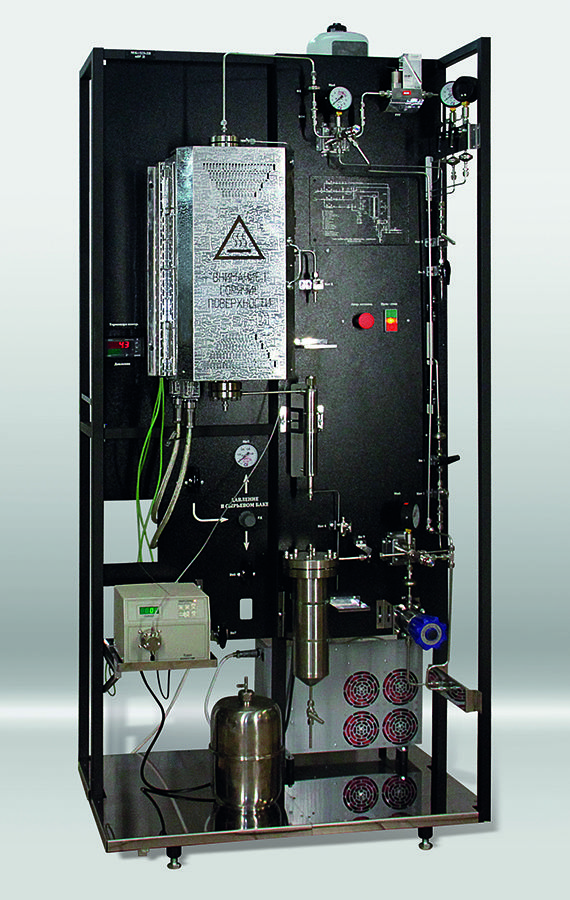

Pilot coking unit

Application

The facility is designed to simulate and study the processes of delayed coking that take place at heightened temperature and pressure in a stainless steel reactor made in the form of a flask with a spherical bottom and a removable lid. The installation allows you to obtain experimental data, to select and optimize the parameters of the process, to test various options for raw mixtures, to determine the material balance of the process, the characteristics of the product.

Specifications

The Unit is a compact frame design designed for operation in a dry, heated room. The electrical safety installation meets the requirements of class 1 type N in accordance with GOST 12.2.025-76.

Operating conditions:

- Environmental temperature from +10 to +35˚С;

- Relative humidity not more than 80% at a temperature of 25˚С;.

- power supply - single-phase AC network with voltage of 230-240 V and frequency of 50-60 Hz.

- The average life of the appliance of plant is 5 years.

| Specifications | Value |

| Range of operaing pressures, MPa | 0÷0,6 |

| Reactor operating temperature range, 0С | 50÷550 |

| Accuracy of a task of temperature, 0С | 1 |

| Absolute deviation of maintaining temperature, 0С | ±0,2 |

| Reactor material | steel 12х18Н10Т |

| Input power no more than, kW | 3 |

| Overall dimensions, mm | 1600х1100х495 |

| Weight, kg | 240 |

| Mode | continuous |

Submit application

You may be interested

News

Our partners

Medireach India Private Limited

National Research Nuclear University "MIFI"

CJSC «Rosshelf»

The Ministry of Defence of the Russian Federation

Federal space Agency («Roscosmos»)

OJSC «Salavatnefteorgsintez»

OJSC «Nizhnekamskneftekhim»

OJSC «Tatneft»

OJSC «Tobol'sk-Neftekhim»

OJSC «Caustic», Sterlitamak

Evrohim

OJSC «Nevinnomyssky Azot», Nevinnomyssk.

OJSC «Cherepovetkyi «Azot»

OJSC «Acron», Veliky Novgorod

OJSC «Halogen», Perm

OJSC «Kazanorgsintez»

OJSC «Severstal»

LLC «Kirovo-Chepetsk chemical company»

OJSC «MMC "Norilskyi Nickel»

OJSC «Nizhnekamskshina»