Purpose

1.1. The laboratory catalytic dewaxing unit is designed to remove normal paraffinic hydrocarbons from oil fractions. Since normal hydrocarbons have a high pour point, their removal lowers the pour point of the oil fraction.

Catalytic dewaxing is characterized by the fact that at high pressure, temperature and excess hydrogen, long molecules of normal paraffins are split and isomerized.

2. Technical Specifications

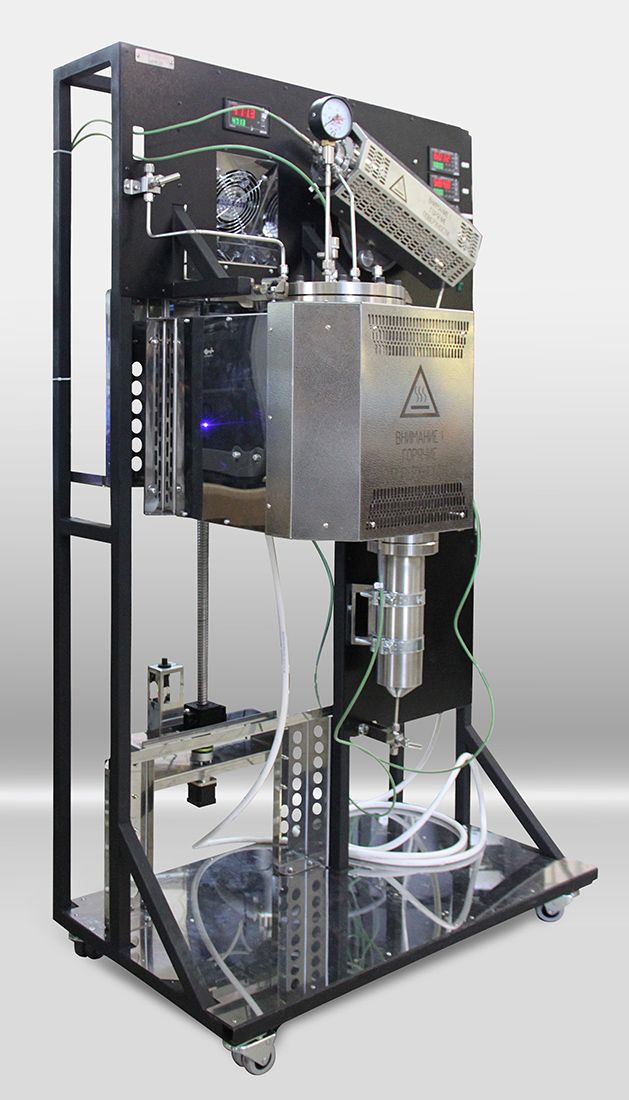

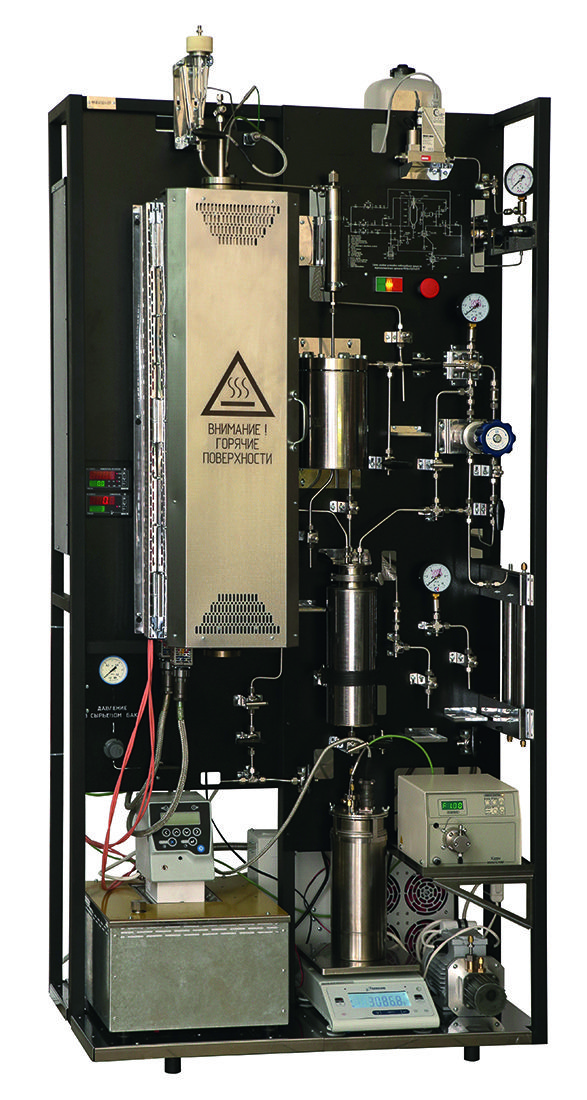

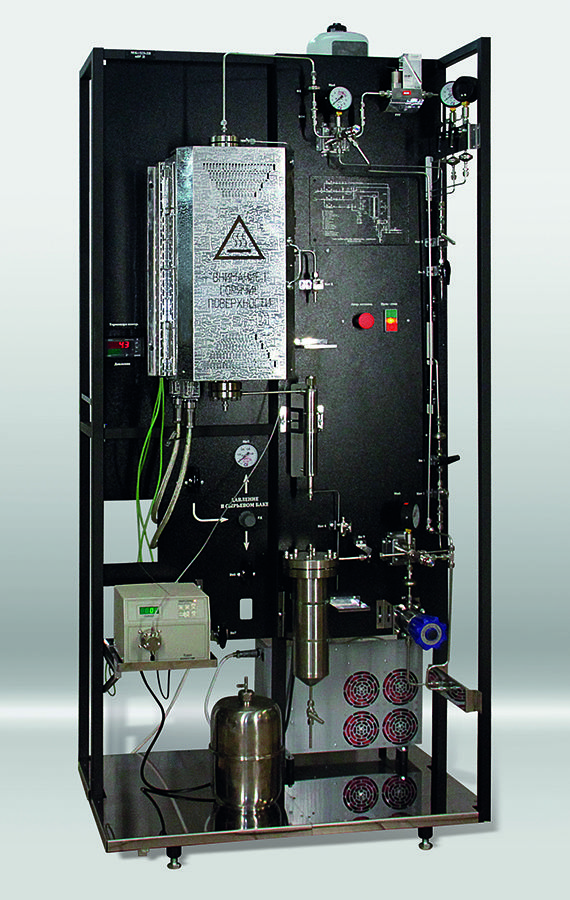

2.1. The unit is a rack with shut-off valves, a heating reactor and a control unit attached to it.

2.2. Unit for electrical safety meets the requirements of class 1 type H in accordance with GOST 12.2.025-76.

2.3. Operating conditions:

· environmental temperature from +10 to + 35˚С

· relative humidity not more than 80% at a temperature of 25 ° C (77 ˚F);

· power supply - single-phase AC network with voltage of 220 V ± 10% and frequency of 50 Hz.

2.4. The average service life of the unit is 5 years.

2.5. Specifications are given in table. 1

Table 1

|

Technical characteristics of the hydrotreatment and hydrogenation unit |

Value |

|

Reactor: pcs |

1 |

|

Reactor volume, ml |

365 |

|

Material |

12Х18Н10Т |

|

Inner diameter, mm |

24 |

|

Length, mm |

900 |

|

Operating temperature range, 0С |

20÷600 |

|

Operating pressure range, MPa |

0÷10 |

|

Removable pocket for thermocouples, mm |

660 |

|

|

|

|

Reactor oven: pcs |

1 |

|

Oven type |

Swing |

|

Number of temperature-controlled zones, pcs |

4 |

|

Length of the complete heated zone of the oven, mm |

700 |

|

The length of each of the four temperature-controlled zones, mm |

150 (2 pcs) 200 (2 pcs) |

|

The length of the isothermal zone of the oven, mm |

400 |

|

Power consumed by each isothermal zone, W |

400 |

|

Power consumed by all three furnace zones, W |

2000 |

|

Temperature setting resolution, 0С |

1 |

|

|

|

|

Hydrogen flow shaper: pcs |

1 |

|

Shaper type, GFCE 1 |

Bronkhost |

|

Supported flow rate range, ml/min |

0-3000 |

|

Inlet pressure, bar |

40 |

|

|

|

|

Nitrogen flow shaper: pcs |

1 |

|

Shaper type, GFCE 2 |

Meta-chrom |

|

Supported flow rate range, ml/min |

0-1000 |

|

Inlet pressure, bar |

0-6 |

|

|

|

|

Air flow shaper: pcs |

1 |

|

Shaper type, GFCE 3 |

Meta-chrom |

|

Supported flow rate range, ml/min |

0-1000 |

|

Inlet pressure, bar |

0-6 |

|

|

|

|

Raw material consumption shaper: pcs |

1 |

|

Shaper type, liquid pump |

KAPPA 10 |

|

Supported flow rate range, ml/min |

0-10 |

|

Outlet pressure, bar |

0-400 |

|

|

|

|

Raw material container: pcs |

1 |

|

Volume, l |

3 |

|

Maximum pressure, bar |

1 |

|

Working pressure, atm |

0,2-0,5 |

|

Raw materials |

gasoline |

|

|

|

|

Unit: pc |

1 |

|

Operating cycle of the unit, h |

120 |

|

Calculated inlet gas pressure H2, N2, MPa |

10 |

|

Actuation pressure of mechanical safety valves, bar |

36 |

|

Supply voltage |

220V 50Hz |

|

Power consumption of the entire unit, no more than, kW |

4 |

|

Weight, kg |

120 |

|

Overall dimensions, mm |

1800х865х550 |

|

The technical characteristics of the purchased units used are given in the technical documentation for these units supplied with the unit. |

|