Application

Laboratory unit is designed to determine the activity and selectivity of isobutene dehydrogenation catalyst (KDI; KDI-M) in a fluidized bed. Continuous automatic operation mode allows to carry out tests of KDI and KDI-M resource and to explore the physico-chemical properties of pulverized catalysts as well as the technological parameters of the fluidized bed.

Technical specifications

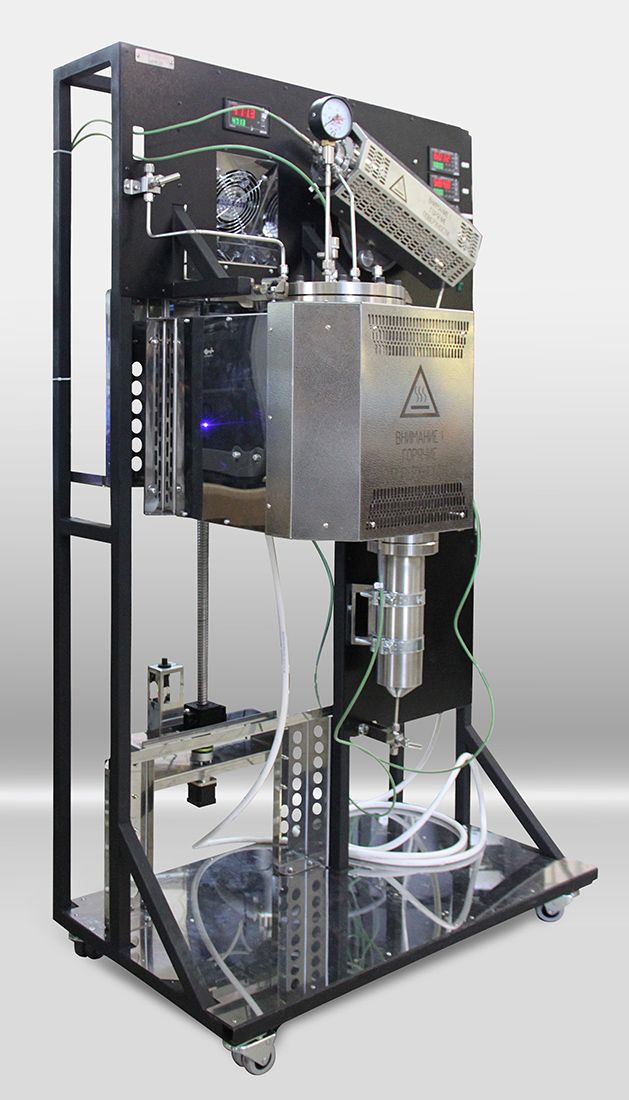

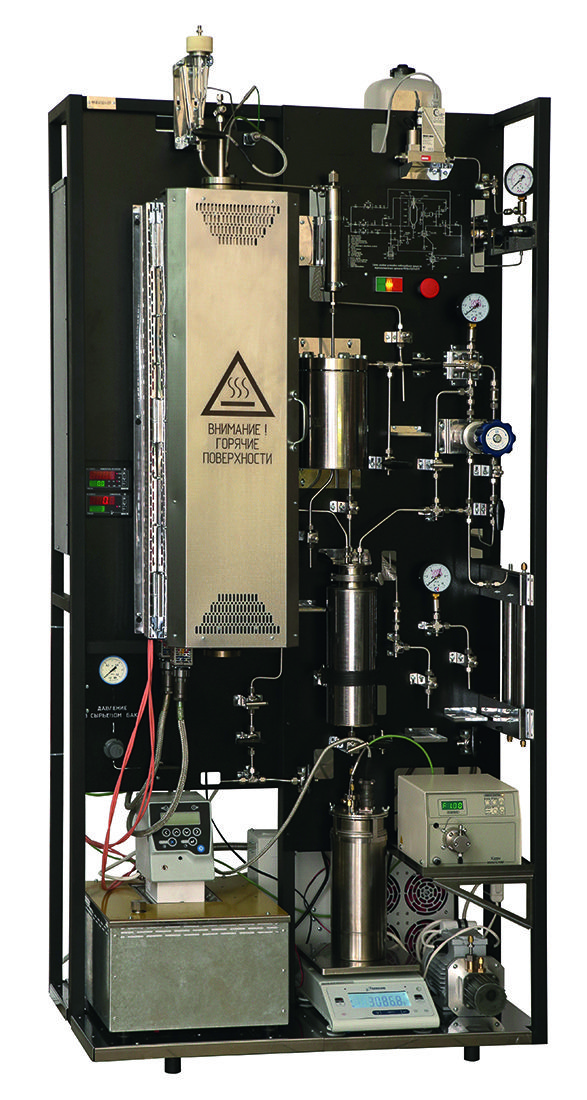

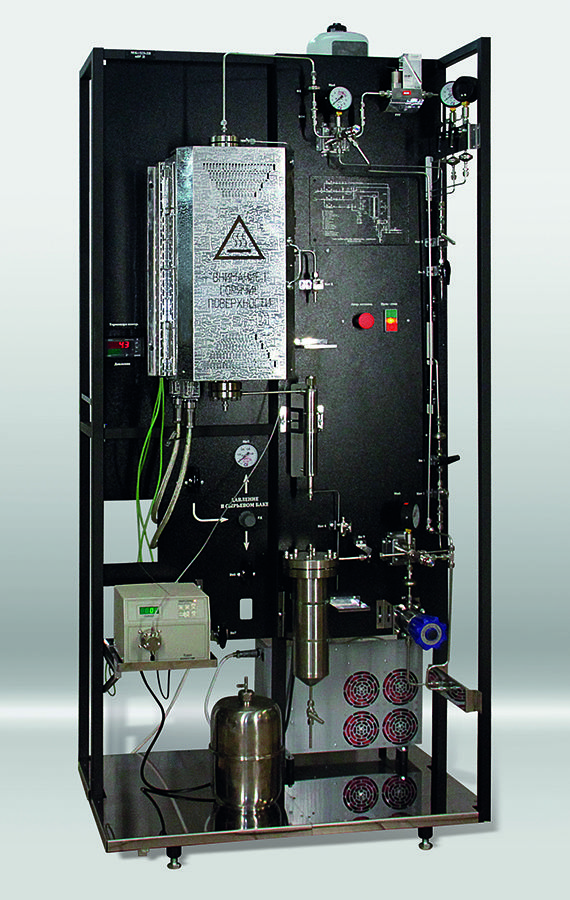

· 800mm long reactor with an internal diameter of 30 ± 1mm and an operating temperature range from 50 to 800°C

· Four gas flows formation (isobutane, nitrogen, air, hydrogen), based on electronic regulators of gas mass flow;

· Power supply 230V 50Hz;

· Dimensions (W x D x H): 800x800x2000mm;

· The unit is placed in a protective ventilated cabinet with a glass lockable door.

Features

· The reactor is made of titanium or nickel-free steel;

· Control thermocouples are located in 4 reactor zones;

· Reactor casement oven with 4 heated zones and operating temperature range from 50 to 800°C;

· Oven automatic accelerated cooling system;

· Gas flows formation error is less than 0.5%;

· Gas flows automatic setting required for the supply and mixing of gases entering the reactor;

· Reactor pressure monitoring to assess the degree of filter clogging;

· Filters’ reverse purging for its cleaning;

· Catalyst automatic loading and unloading;

· Heated reactor automatic filling with nitrogen in case of an abnormal power outage;

· Automatic hydrogen supply for KDI and KDI-M regeneration;

· Gas flow heater before the reactor with a temperature range from 20 to 500°C.

Conducting the KDI and KDI-M test

· The user's software allows you to create an unlimited number of KDI and KDI-M test profiles;

· Synchronization of the Chromatograph with the Net Chrome software allows analyzing the product without user participation;

· Chromatographic determination of the qualitative and quantitative composition of permanent (H2, O2, N2, CO, CO2) and hydrocarbon (alkanes, alkenes up to C6) gases with an assessment of activity and selectivity;

· Execution of an unlimited number of tests cycles;

· Automatic injection of the required amount of one or different catalysts;

· Automatic unloading of the catalyst after the tests completion.