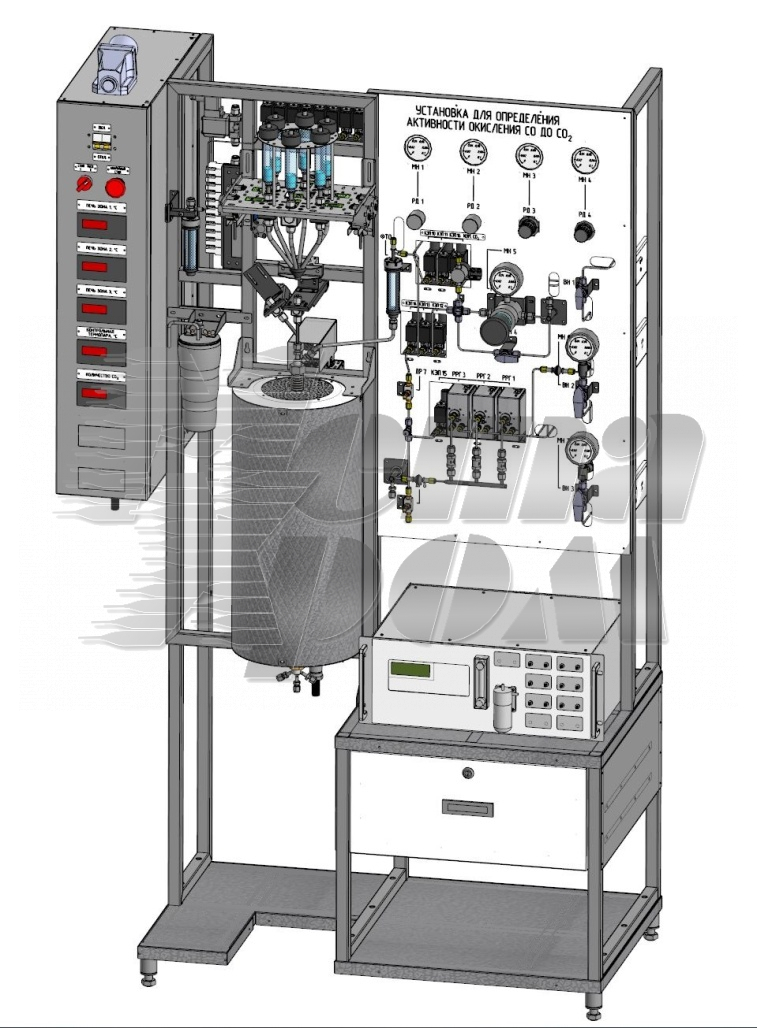

Application

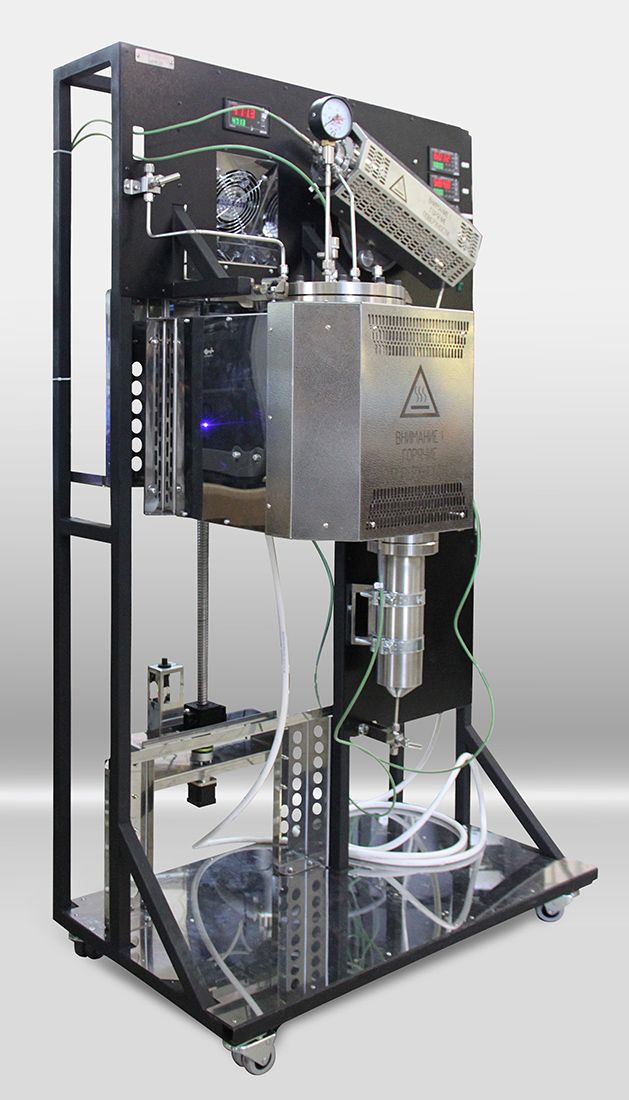

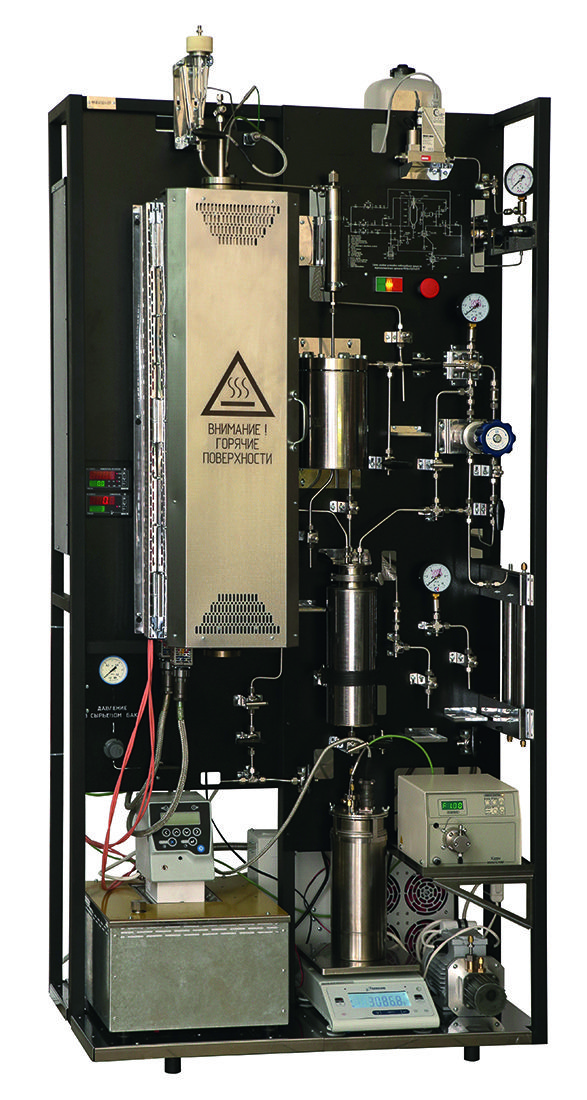

The unit is designed to determine the activity of catalysts during the oxidation of CO to CO2 (CO index). This indicator is important for the catalyst regeneration process, since incomplete oxidation of CO can lead to an open flame in the regenerator because of the mixture of CO and air is flammable and explosive.

The method requires mixture of CO with inert gas and air passing through fluidized bed catalyst in a quartz reactor at temperatures above 600 °C and analyzing the exhaust gases using a gas analyzer designed to measure the concentration of carbon dioxide.

Operating conditions:

· Ambient temperature from +10˚С to +30˚С;

· relative air humidity no more than 80% at 25˚С temperature;

Technical specifications

|

Technical specifications |

Value |

|

Input Air Pressure, MPa |

0,7-0,8 |

|

Nitrogen Flow Rate, less than, l/min |

1,0 |

|

N2+CO 5% Operating Pressure, MPa |

0,3±0,5 |

|

Input Nitrogen Pressure, MPa |

0,4±0,5 |

|

Nitrogen Purity |

99,9999% |

|

Input Air Humidity, no more than |

30% |

|

Operating temperature range of 3-zone oven with reactor |

50°C - 750°C |

|

Reactor material |

silica glass |

|

Catalyst loading container volume, ml |

15 |

|

Catalyst discharging container volume, ml |

400 |

|

Humidifier volume, ml |

20 |

|

Reactor length, mm |

600 |

|

Reactor diameter (inner), mm |

12 |

|

Overall dimensions (WхHхD), mm |

1100×2000×600 |

|

Voltage, V |

230 |

|

Frequency, Hz |

50 |

|

Power Consumption, less than, kW |

2 |

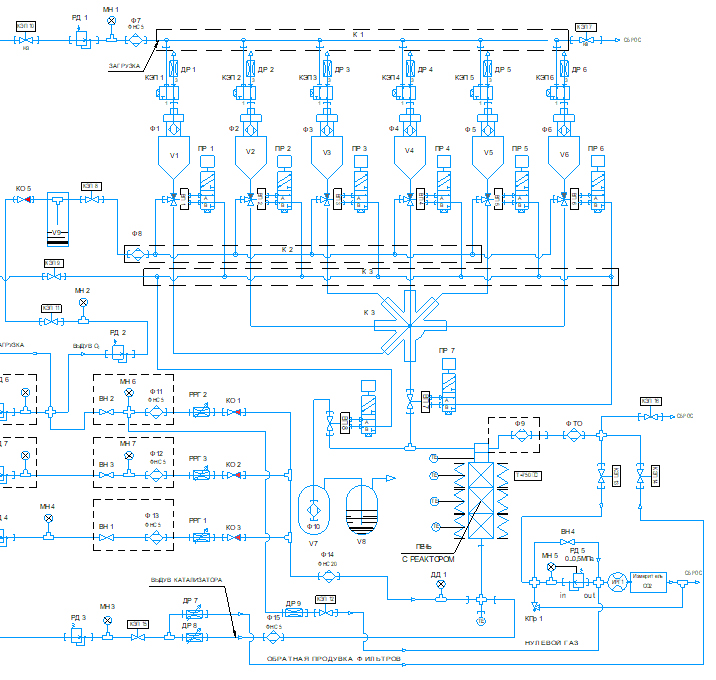

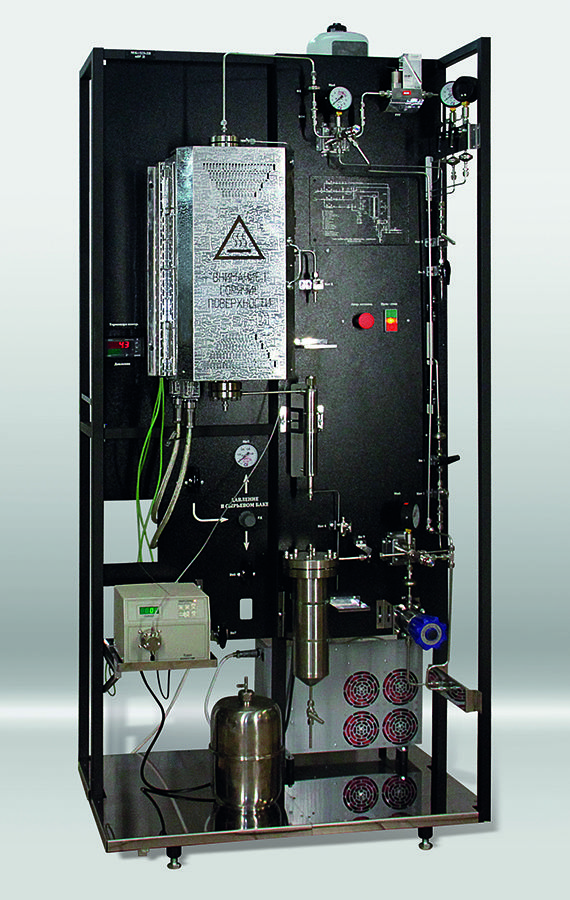

Unit flow diagram