Application

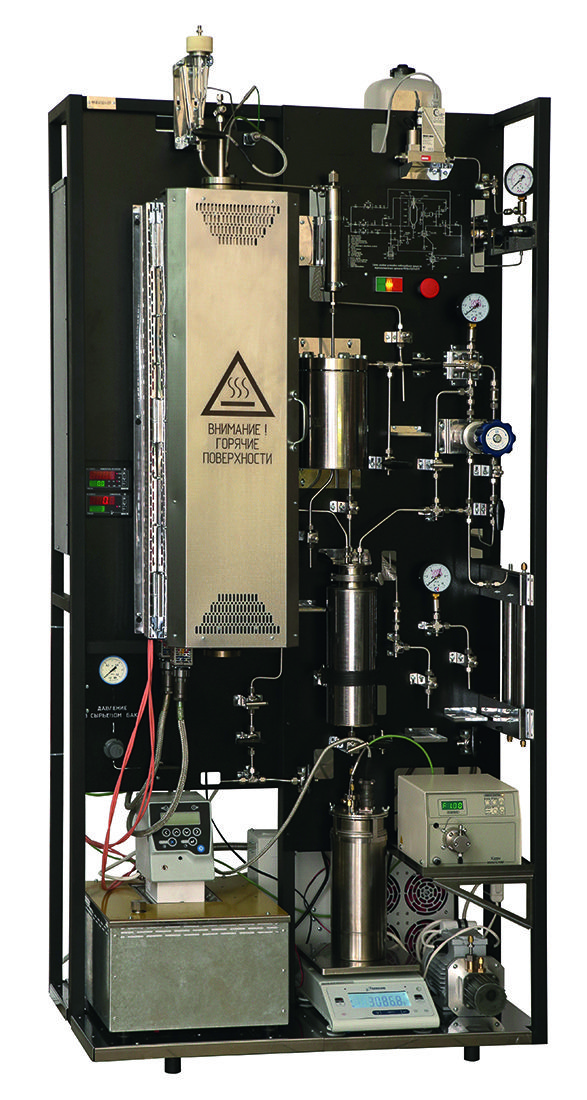

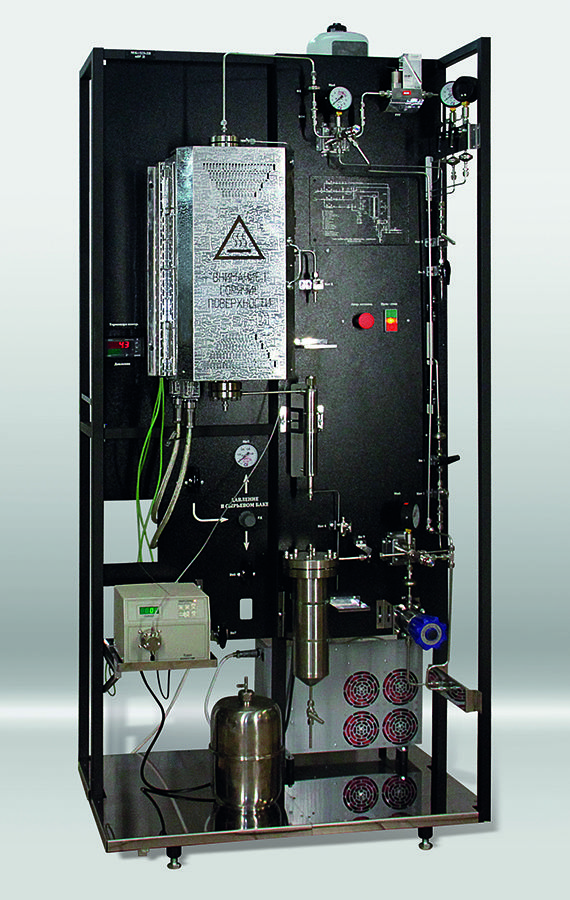

The autoclave is designed to simulate various chemical processes that take place at elevated temperatures and pressures.

Specifications

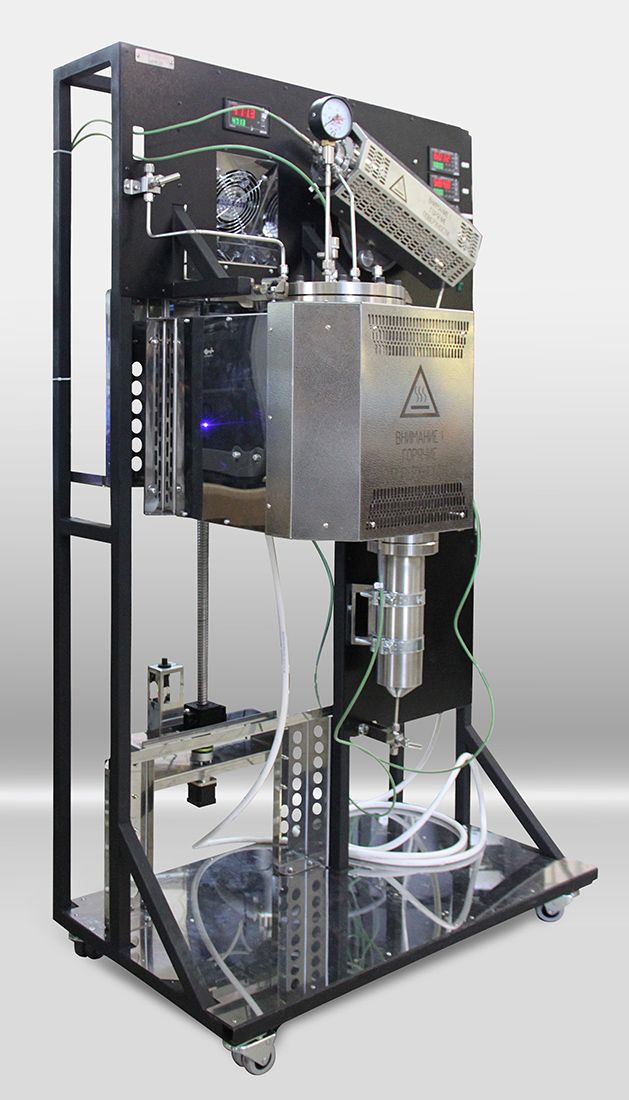

The autoclave is a flask with a spherical bottom made of stainless steel, equipped with a jacket through which the coolant circulates. The flask is hermetically sealed with a stainless steel spherical lid, on which a magnetic coupling of the stirrer drive, a gateway for loading bulk, liquid product, a safety valve, a pressure sensor, a pressure relief valve, a demountable liquid phase sampler, and a thermocouple for measuring the temperature in the autoclave reactor is placed. The flask with the lid is fixed on the bed, which includes the bracket for attaching the stirrer drive, an electric lift to help provide installation and dismantling of the autoclave flask, and a panel with elements for indicating the autoclave operation parameters. The autoclave is made in the form of a compact modular design, designed for use in a dry, heated room with forced ventilation. The electrical safety autoclave meets the requirements of class 1 type N in accordance with GOST 12.2.025-76.

Operating conditions:

- Environmental temperature from +10 до +35˚С;

- Relative humidity not more than 80% at a temperature of 25˚С;.

- Power supply - single-phase AC network with voltage of 230-240V and frequency of 50-60Hz.

- The average life of the appliance of autoclave is 5 years.

|

Specifications of hydrotreating and hydrogenation unit |

Value |

|

Range of operaing pressures, MPa |

-0.1 ÷ 10 |

|

Reactor operating temperature range, 0С |

-30 ÷ +450 |

|

Autoclave flask volume, l |

0,1 ÷ 20 |

|

Stirrer rotation speed, rpm |

up to 1500 |

|

Bottom valve |

included |

|

Flask connection and flange caps |

included |

|

Lifting unit |

included |

|

Power supply, single phase |

230-240 V 50-60 Hz |

|

Input power no more than, kW |

0,5-6 |

|

Mode |

continuous |

|

Stirrer type |

- gate stirrer - propeller stirrer - anchor stirrer - ribbon stirrer |