System includes digital ionization-thermocouple vacuum gauge with continuous pressure measurement range, automatic sensor degassing and digital gas leak, that includes two or more in-built precision gas flow regulators with thermometric gas flow meters, and that allows the unit to work in the mode of autonomous inlet of the set gas flow rates independently from inlet pressure.

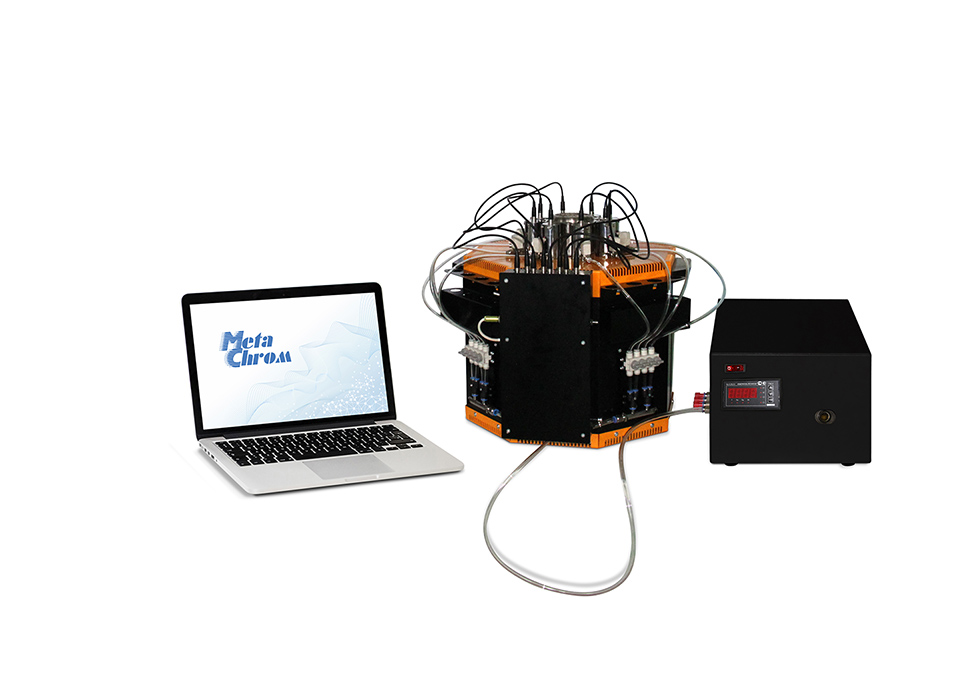

Photo: System of pressure maintenance in vacuum gauge (connection scheme)

Letters on the scheme indicate:

B — 220V power wire

С — thermocouple lamp

D — ionization lamp

E — the electronic control unit of the leak valve

G — signal cables

H — cable for data exchange with IBM

J — IBM

L — cable for data exchange between the units

M — cable for connecting additional devices to the network

N,O — working gases inlet

P,R — output of the working gases.

Control of system units is done from keyboard on the corpus (autonomously) and also remotely from computer via network interface

System is designed for automatic control of working gas consumption (inert and reactive), for example, magnetron and ion-beam technological processes of application of metals, their nitrides, oxides, carbides, carbonitrides and others with one or more sprayers in the terms of the constancy or reproducibility of discharge power. System works in continuous range of pressure values without switching of measurement limits from 100

Vacuum gauge sensors convert pressure value in the vacuum chamber into electrical signals. These signals enter normalization amplifiers and then proceed to controller. Controller transfers processed pressure value to multichannel leak valve of working gases. Working gases consumption is maintained on the level, which saves pressure value in vacuum chamber during processes of coating application, and also saves composition of the flow (gas ratio) that forms the coating.

Readings of thermocouple and ionization sensors are displayed on vacuum gauge screen simultaneously.

As a result of competition “Best Russian measuring device-2008”; devices “Digital vacuum gauge with continuous extended measuring range” and “Digital gas leak” were recognized as winners and got corresponding diplomas.

Set and measured pressure is shown on leak valve display, also gas flow through channels and preset and measured proportion of gas flow is shown.