Thermodesorber is used with chromatographs like Crystallux-4000M, Crystallux-4000, Crystall-2000, etc. for sample injection into chromatographic column. First of all thermodesorber is designed for analysis of volatile organic compounds present in atmosphere air, working area air, industrial exhaust.

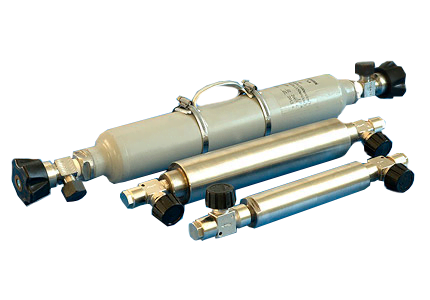

Photo: Thermodesorber

Work of this device is based on thermodesorption of volatile components, accumulated in the capsule with thermodesorber sorbent, through which tested gas was pumped beforehand (for example air) with further split in chromatographic column. Type of sorbent or their combination is chosen depending on nature of the analyzed substances. In most cases such sorbents like Tenax TA, Tenax GR, Chromosorb or Polysorb are used.

Besides, solid samples placed in specific capsule can undergo thermodesorption (for example paint, plastic, paper with oil on it, etc.). While heating this capsule volatile substances are released form the materials placed inside, and they are further analyzed by chromatograph. Thermodesorption is also used in geochemical soil exploration.

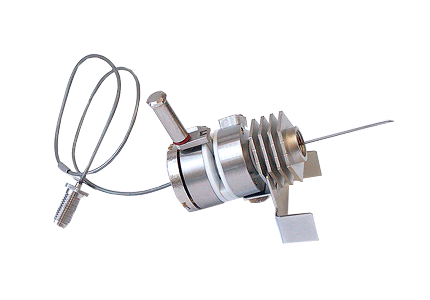

Thermodesorption is performed through heating of the capsule to fixed temperature at a speed over 300°C/sec. Peculiarity of this construction of thermodesorber and its high operating characteristics is in the absence of parasitic volume between thermodesorber capsule and chromatographic column. This allows to work with high resolution of chromatographic peaks either with capillary or packed columns. Thermodesorber construction is under patent protection.

Thermodesorber is installed onto chromatograph evaporator, it is equipped with valve for shutoff of gas-carrier line during demounting of the rod with capsule from thermodesorber. Capsule is inserted into the heated evaporator with the help of rod if the valve is open (lower position). Capsule purge with gas-carrier for expelling the air is possible if the rod is in upper position.

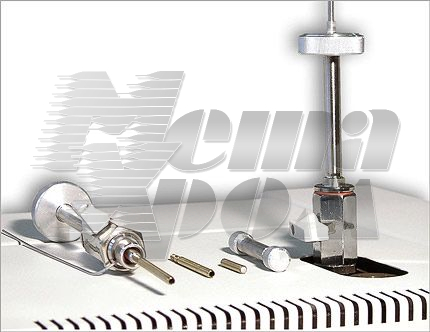

Thermodesorber is supplied with set of capsules for sorbents, capsules for solid samples, container for storage of capsules with samples and input device for input of capsules into the evaporator of chromatograph.

META-CHROME PRODUCES THREE TYPES OF THERMODESORBERS: TDS-2, TDS-3 AND TWO-STAGE TDS-4

TDS-2 is a syringe (see Fig. 1), which is installed on the evaporator of the chromatograph. The device is equipped with a valve that cuts off the carrier gas line when the rod with the sorption tube is removed from the thermal desorber. When the valve is open, the stem is lowered to the lower position and the sorption tube is introduced into the injector brought to the required temperature. In the conditions of the upper position of the stem, it is also possible to displace air by purging the sorption tube with a carrier gas.

Fig. 1

TECHNICAL CHARACTERISTICS TDS-2

| Name of the capsule | Value |

| Heating time to desorption temperature | no more than 1 sec. |

| Cooling time when moving to a cold zone | no more than 10 seconds. |

| Outer diameter | 5-0,1 mm |

| Dimensions of the sorbent chamber: | diameter 3,4+0,3 mm |

| length 52 mm (470 µl) | |

| Volume (for solid samples) | 90 µl |

| Operating temperature ranges* | from 50° to 400 °C |

| Overall dimensions (height with the rod fully extended) | 320 mm. |

| Weight |

0,325 kg. |

* - the desorption temperature, the discreteness of its setting and the maintenance error correspond to the evaporator temperature of the chromatograph used.

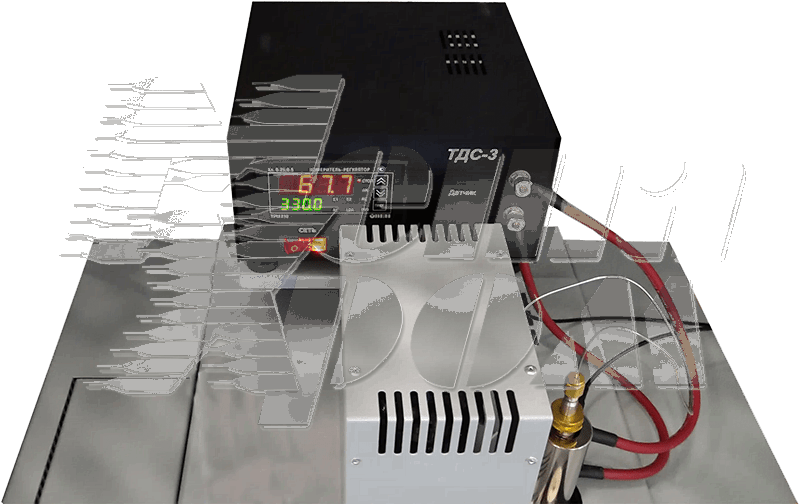

The TDS-3 thermodesorber includes a heating column with a sorption tube, which is installed on the chromatograph injector and a control unit located on a special bracket on the right side panel of the chromatograph (see Fig. 2).

Fig. 2

TECHNICAL CHARACTERISTICS TDS-3

| Name of the capsule | Value |

| Desorption temperature (column warming up), 0С | to 400 |

| Heating rate, 0С/min | not less than 500 |

|

Cooling time when moving to a cold zone is |

no more than 10 seconds |

| Cooling time from 300 0С to 50 0С, min. | no more than 10 |

|

Operating mode |

continuous |

|

Power consumption, W |

no more than 250 |

|

Sorption tube dimensions, (Ø, length), mm Material glass, stainless steel |

5/110, 5/114, 6/115, 6,35/89 |

|

Power supply from |

from 187 to 242 V, 50 Hz. |

|

Displaying the measured temperature and setting the temperature on the display |

There is |

| Discreteness of setting the desorption temperature,0С |

0,1 |

TDS-3 is used in conjunction with a 6-port valve to switch gas flows.

One-stage thermal desorption is the simplest desorption option. In this case, the substances are directly transferred from the sorption tube to the chromatographic column. Since the volume of the sorbent in the tube is large enough, it is impossible to provide “instant” desorption of the components. because of this, the chromatographic separation is worse.

To enter the analytes in a narrow zone into a chromatographic column, two-stage thermal desorption is used. When carrying out a two-stage thermal desorption, the components extracted from the sorption tube are preliminarily focused in a cold trap and then sent to a chromatographic column in a narrow zone.

Focusing provide by trapping components in a trap. The trap is filled with sorbent and cooled using Peltier elements. Small volume of the sorbent makes it possible to carry out fast desorption and injecting the sample into the chromatographic column with a narrow zone.

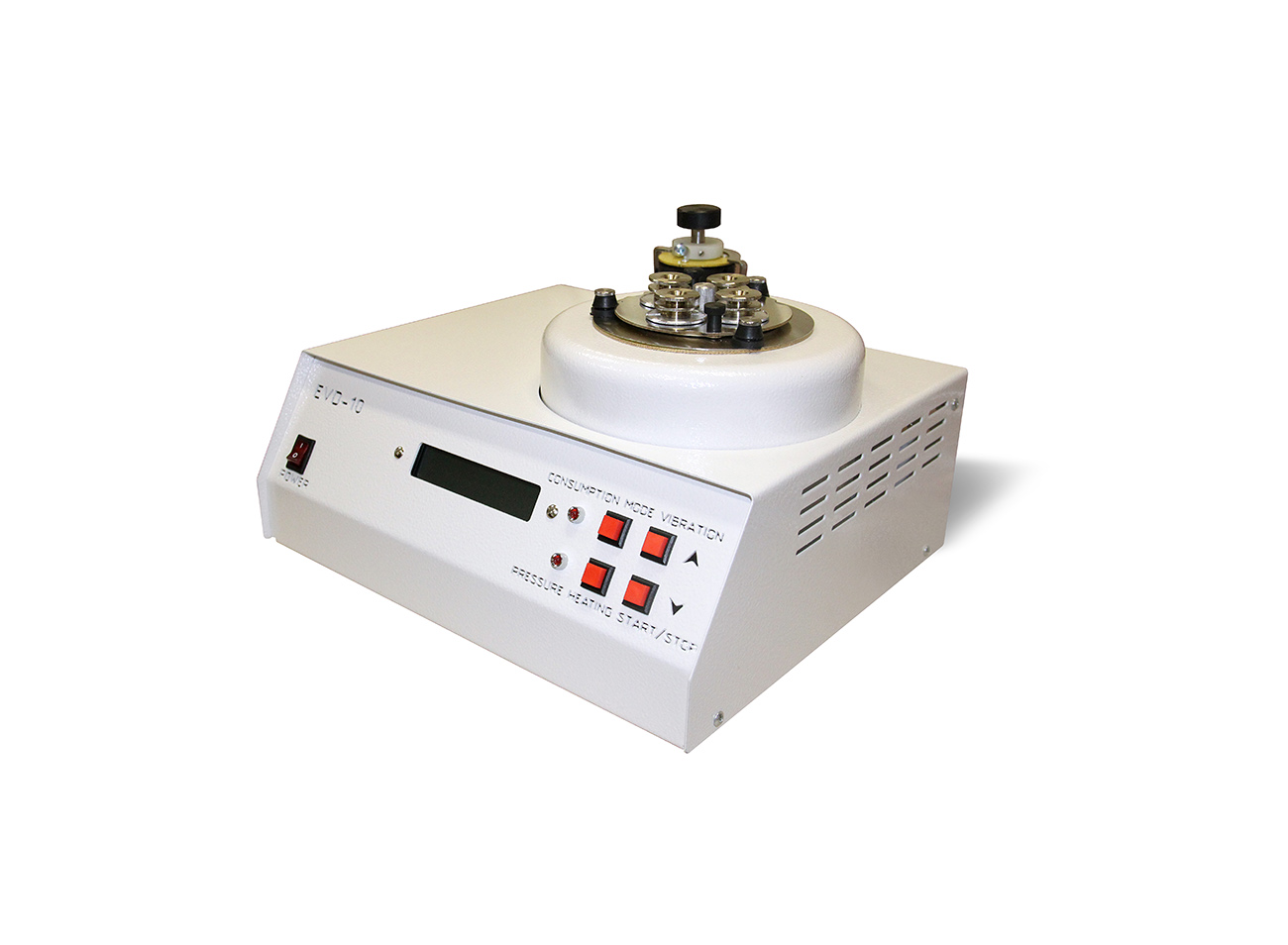

The design of the two-stage thermal desorber is distinguished by the presence of a two-position rotary 6-port thermostatic valve, which provides switching of gas flows at the stages of desorption and sample introduction into the chromatograph and a cooled trap, which provides concentration of the sample desorbed from the sorption tube.

The TDS-4 includes the thermal desorber itself (sorption tube thermostat, cryo trap, automatic switching valve, touch control panel), a heated transition line, which is installed in the evaporator (see Fig. 3).

Fig.3

TECHNICAL SPESIFICATION OF TDS-4

| Name of the capsule | Value |

| Thermal desorption temperature, 0С | to 400 |

| Sorption tube heating rate, 0С/min | up to 500 |

| Trap temperature, 0С | from minus 25 to 400 |

| Trap heating rate, 0С | up to 2000 |

|

The method of heating the trap |

is direct |

| Tap heating temperature, 0С | to 250 |

| Heating temperature of the transition line, 0С | to 250 |

|

Operating mode |

Continuous |

|

Sorption tube dimensions, (diameter; length), mm. 5/114 (on order 6/115, 6.3 / 89 and their combinations) Material glass, stainless steel Tube material glass or stainless steel (SS316) |

5/114 (on order 6/115, 6,3/89 and their combinations) |

|

Material tube

|

glass, stainless steel Tube material glass or stainless steel (SS316) |

| Method of trap cooling | without using liquid refrigerant |

|

The number of regulated gas streams is |

not less than 2 |

|

Availability of an automatic leak test function |

There is |

|

Availability of the function of automatic purging of the sorption tube |

There is |

| Power supply from | from 187 to 242 V, 50 Hz |

| Power consumption, W |

no more than 700 |