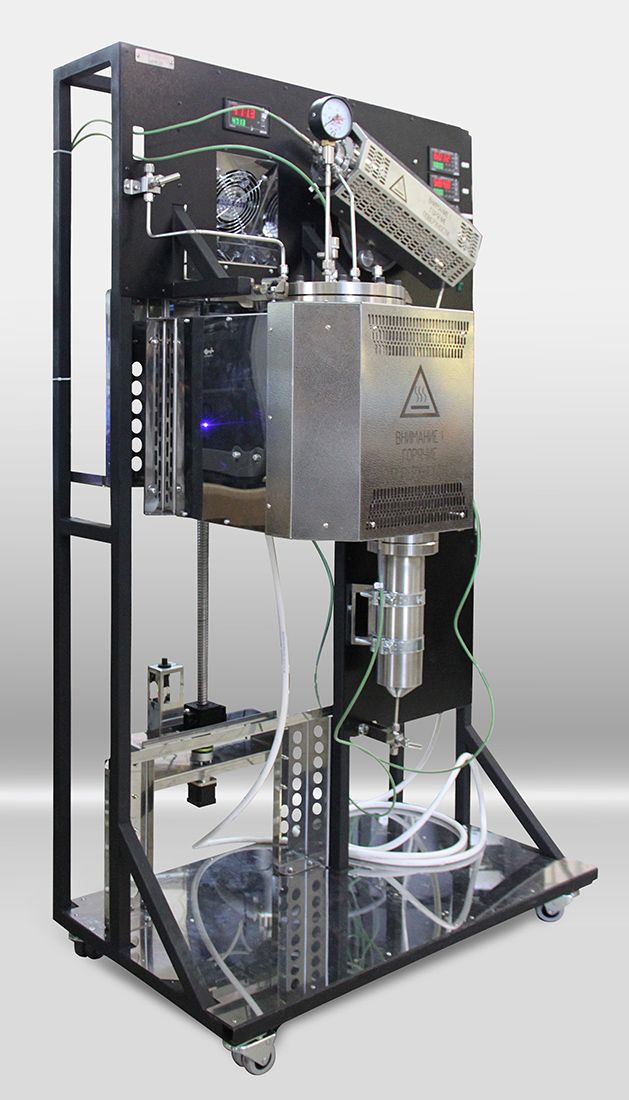

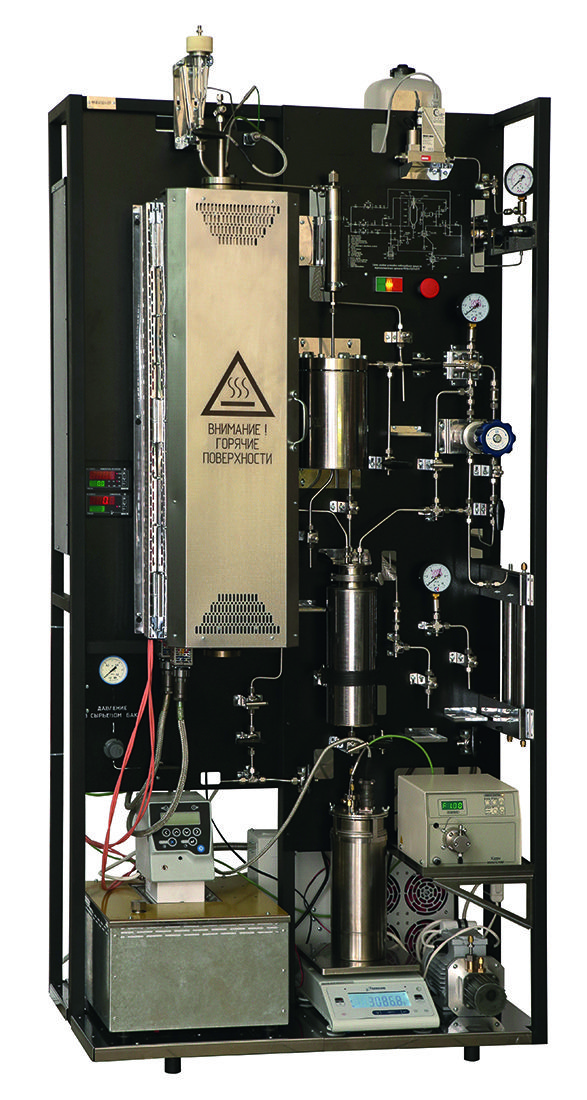

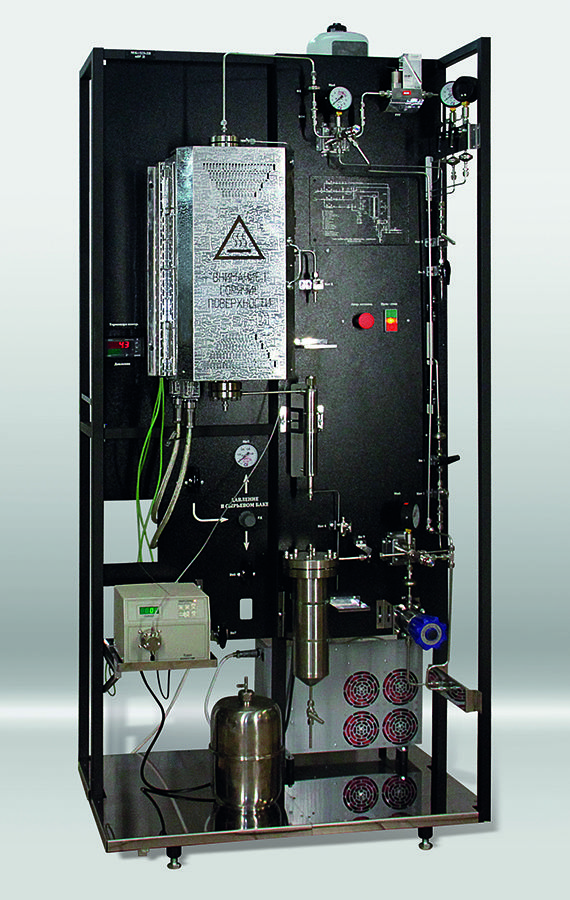

Automatic attrition tester

Automatic attrition tester by air jet for FCC catalysts for fluidized bed cracking by ASTM D5757-22

Application

Automatic attrition fluidized bed tester by air jet for various catalysts including FCC designed to determine the comparative characteristics of attrition of FCC by friction of an air jet according to ASTM D5757-22.

It is used for testing with particles of spherical of irregular shape (size from 10 to 180 microns).

Abrasion is achieved by fluidizing the sample with moist air jets. The percentage of fines (less than 20 microns) after the 5 hour test is the Air Jet Abrasion Index (AJI).

Specifications

| Specifications | Value |

| Operating pressure range, MPa for apparatus gas supply | 0,8±0,1 |

| Range of air flow for unit gas supply, at least (l / min) | 20 |

| Absolute deviation of maintaining air flow at a flow rate of 10 l / min., l / min. | ±0,05 |

| Input power no more than, kW | 0,2 |

| Overall dimensions, mm | 555x755x1700, 30 |

| Abrasion pipe made of steel with dimensions, mm | 710±10, 35±0,5 |

| Three sapphire nozzles, diameter and length, mm |

0,381±0,005, 2,0 |

| Mode | continuous |

| Control: microprocessor with tactile control for setting the display and automatic maintenance of the installation parameters and mathematical processing of the analysis results | |

| Convergence of results when testing the same catalyst | not more than 0,1% |

Operating conditions:

- environmental temperature from +10 до +30˚С;

- relative humidity not more than 80% at a temperature of 25˚С;.

- atmospheric pressure from 84 to 107 kPa (from 630 to 800 mm Hg);

- power supply - single-phase AC network with voltage of 230-240V and frequency of 50-60 Hz.

This installation has the following advantages:

- Strictly complies with the new ASTM method.

- Suitable for FCC catalysts (with and without steam) and analogs.

- Automatically maintains with high accuracy the values of mass air flow, humidity, has a system for automatic removal of catalyst residues from the walls of the settling chamber before the end of the analysis and a minimum spread of sapphire nozzle diameters that meet the requirements of ASTM 5757-22, which together provides independence from conditions environment and has the highest repeatability of the analysis results of no more than 0.1% and the minimum time to reach the operating mode (no more than 10 minutes) in comparison with all currently produced abrasion testers.

- The unit has wheels with foot operated locks and can be easily moved around the room, i.e. moved out when not needed and roll out for analysis.

- The unit is equipped with the necessary tools and expendable materials for operation for two years, including replaceable filters.

- The tester is certified as a test facility.

Submit application

You may be interested

Our partners