The gas chromatograph «Crystallux-4000M» is fully automated from sample injection to chromatographic data analyzing, including such features as automatic control of the oven temperature, flow and pressure of carrier gas and auxiliary gases, detector automatic ignition, flame burning control, measurements of detector signals using a 24-bit ADC.

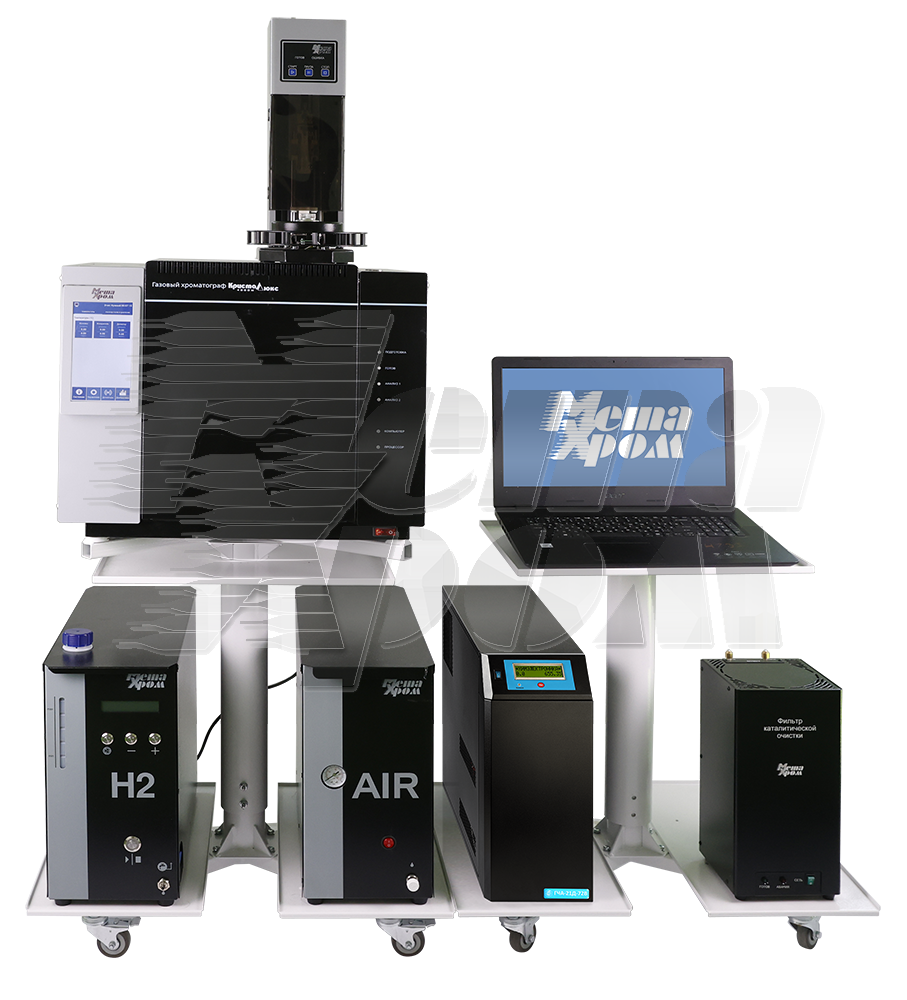

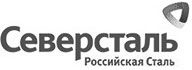

Photo: gas chromatograph «Crystallux-4000M» and additional equipment.

- Chromatograph «Crystallux-4000M»

- Liquid autosampler HTA

- Personal computer

- Air Compressor

- Nitrogen Generator

- Hydrogen Generator

- Catalytic purification filter

There are more than 30 gas chromatograph basic models, adapted to users’ objectives. The chromatograph consists of an analytical unit, the monitoring and chromatographic information processing control station (for example PC), NetChrom software compatible with Windows and Linux. Additional software is also supplied: natural gas calorific characteristics calculation, transformer oil diagnostics, Shuhart control cards calculation, multicomponent mixtures identification (for example, vegetable oil, cognac, hydrocarbon fuel, etc.) and external display data output software.

Up to 8 analytical units could be used by 1 computer in real time mode, in addition to control and process responses from the gas chromatograph «Crystall-2000», «Crystallux-4000» and chromatographs of other brands via ADC. Computer, analytical units and chromatograph data exchange is carried out via standard interfaces such as RS-232C, USB and Ethernet. It’s possible to control the chromatograph from up to 3000 m distance. There is a remote chromatograph control panel based on a microcomputer with Windows OC to set the modes and process information without using main PC. The protection level of the NetChrom program version 2.1, according to P50.2.077-2014, is "high".

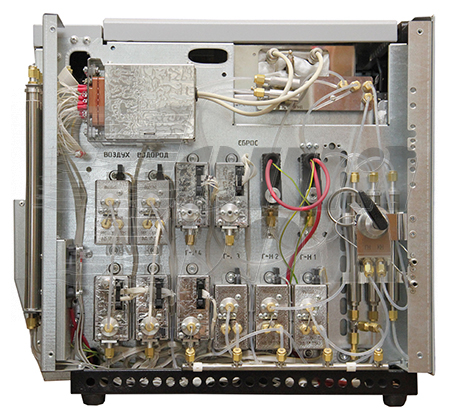

The analytical unit has up to three independent channels for processing information and consists of an oven, a replaceable analytical module, and an electronic gas flow control unit (EGFC). Four detectors can be installed with preorders. To start the analysis, each channel has a «Start» button, which is duplicated by a soft button.

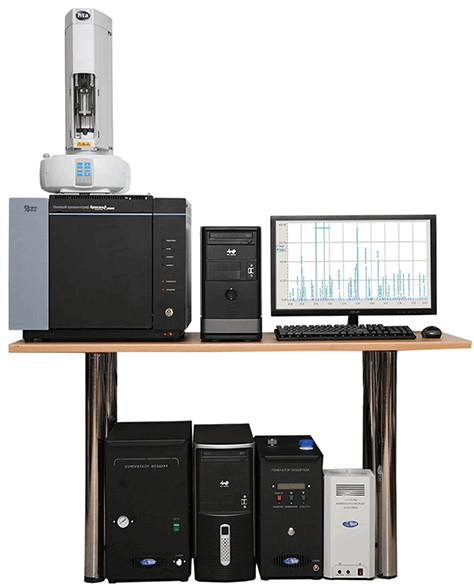

- Hydrogen and air stream splitter

- Switching panel for analytical module connections

- Pressure regulator for the first capillary column

- Pressure regulator for the second capillary column

- Filters

- Gas sampling valve

- Split valves

- Carrier-gas flow regulators

- Power amplifiers

- Hydrogen flow regulator

- Air flow regulator

- Carrier-gas inlet pressure regulator

- Hydrogen inlet pressure regulator

- Air inlet pressure regulator

- Gas collector

Photo: gas chromatograph «Crystallux-4000M»: pneumatic circuit view

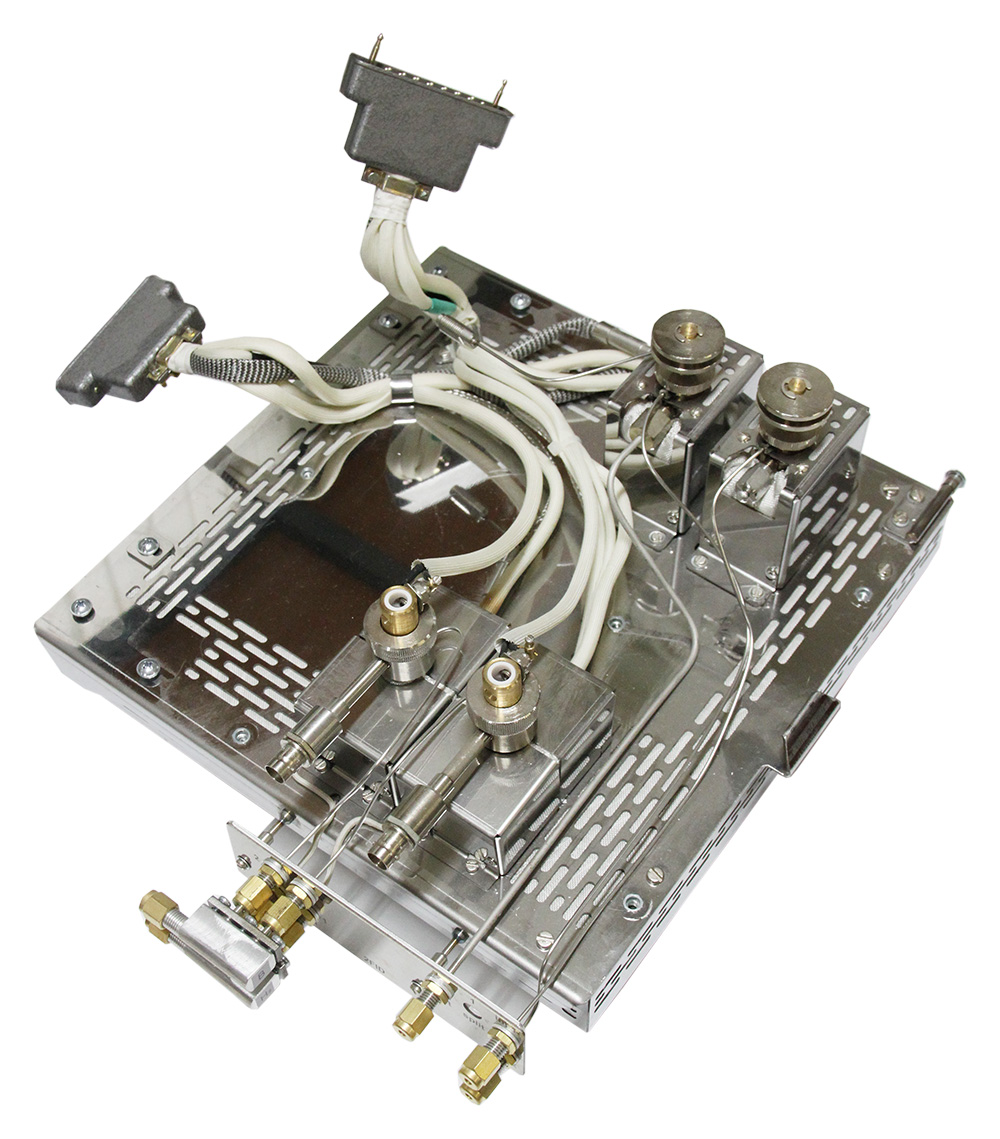

2 models of chromatograph are available: GC with 7 and 14 liters oven. Ovens can contain up to 4 metal/glass columns or 3 capillary columns. Oven is controlled using a new high-precision temperature control algorithm, which help to increase the accuracy of temperature maintenance.

Oven top panel (analytical module) can be locked in a working or inclined position (at a 35° angle - version 1 and at a 12° angle- version 2).

The rotation of the panel makes it easy to install and replace the columns, which corresponds to the oven volume increase in versions 1 and 2 by 3L and 5L, respectively. Thus, the effective volume of the ovens is 10 liters in version 1 and 19 liters in version 2.

On the top panel there is a cover designed to access the gas circuit for its re-switching.

For the negative temperatures generation in oven, 2 type of cryostating devices can be connected to the oven: 1) including refrigerant (liquid nitrogen) with the maximum limit up to -100 ° C and 2) refrigerant free with the maximum limit up to -15 ° C. Simultaneous analysis is possible using two capillary columns with the gas-carrier flows independent control. It’s possible to split the flow downstream the capillary column for two detectors and inject the sample into two columns simultaneously.

- Top cover

- Nuts -radiators of injectors

- «Start» buttons

- Display (touch screen is optional)

- Removable oven door

- Injector membranes' gas relief

- Injectors' gas-carrier supply

- Gas compartment panel

- Oven cooler

- Capillary column

Photo: gas chromatograph «Crystallux-4000M»: oven view

Depending on the chromatograph model, EGFC unit controls from 2 to 7 flows, including hydrogen and air, using electronic gas flow and pressure regulators, while a programming mode for the gas-carrier’ flow and pressure is provided. A new reliable solenoid valve is used to control the flow in the gas flow regulator.

Gas chromatographs «Crystallux» are equipped with an electronic pressure regulator, which sets the flow rate of the gas-carrier through the capillary column. The sample is relieved from the capillary injector (split, split-splitless modes) using an electronic gas flow regulator and a trap, which also serves as a pressure buffer for the vaporized sample. An automatic buffer cut-off is provided using a relief valve when the device is switched off. It’s possible to maintain the optimal capillary column gas mode by programming the gas-carrier flow by pressure, linear velocity or mass flow rate. There are chromatograph’ gas saving and «sleep» modes.

The gases inlet pressure is stabilized by electronic pressure regulators. It’s possible to use two carrier gases, as well as switch them.

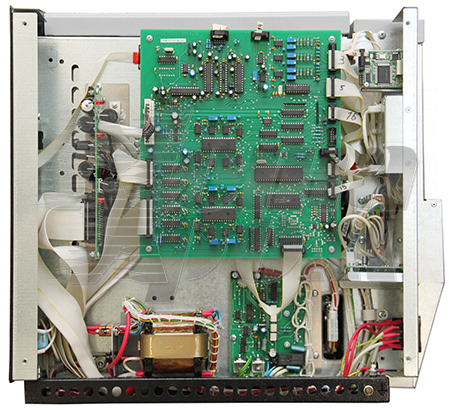

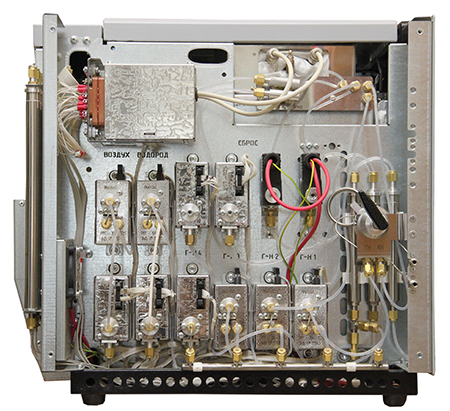

- Controller

- Ethernet Module

- Polarizing voltage Source 200V

- Flash Memory Module

- Switchboard

- Ground terminal

- Power supply

- Power transformer

- Fuse

- Surge protector

- The power button mains voltage

Photo: gas chromatograph «Crystallux-4000M»: EGFC unit

- «Ethernet» workstation connector

- «EXT»-connector for the external devices

- «RS-232» - workstation connector

- Fuses

- IEC connector male

- Carrier gases connectors

Photo: gas chromatograph «Crystallux-4000M»: Rear panel

Technical Specifications of the Gas Chromatograph

|

Parameter |

Value |

|

FID detection limit |

2.0×10-¹² g/s for carbon in hydrocarbons (heptane, propane, etc.); |

|

High-Sensitivity FID detection Limit |

9.0×10-¹³ g/s for carbon in hydrocarbons (heptane, propane, etc.); |

|

TCD detection limit |

8.0×10-¹⁰ g/mL for hydrocarbons; |

|

micro-TCD detection limit |

3.5×10-¹⁰ g/mL for hydrocarbons; |

|

ECD, micro-ECD detection limit |

1.7×10-¹⁴ g/s for lindane; |

|

FPD detection limit |

1.0×10-¹³ g/s for phosphorus in organophosphorus compounds; |

|

NPD (TID) detection limit |

1.5×10-¹⁴ g/s for phosphorus in organophosphorus compounds; |

|

TChD (Thermochemical) detection limit |

5.0×10-¹¹ g/mL for hydrogen; |

|

PID detection limit |

5.0×10-¹³ g/s for benzene; |

|

HID detection limit |

3.0×10-¹³ g/s for carbon in methane; |

|

MSD Signal-to-Noise ratio |

(1500:1) for an injection of 1×10-¹¹ g/µL of octafluoronaphthalene in isooctane |

|

Linear dynamic range FID |

1×10⁷ |

|

Linear dynamic range TCD |

1×10⁶ |

|

Oven volume |

14 (19) L |

|

Column temperature |

from ambient temperature +3°C to +450°C |

|

Temperature setpoint resolution |

0.1°C |

|

Temperature stability |

0.01°C |

|

Temperature programming rate |

from 0.1 to 125°C/min. |

|

Maximum number of isotherms |

not less than 34 |

|

Oven cool-down time (from 400°C to 50°C) |

3 min. |

|

Maximum detector and injector temperature |

450°C |

|

Carrier gas flow rate |

from 0 to 100 mL/min (by special order from 0 to 500 mL/min) |

|

Carrier gas pressure (for capillary column) |

from 0 to 0.40 MPa (by special order from 0 to 1 MPa) |

|

Maximum inlet gas pressure |

0.5 MPa (1.25 MPa by special order) |

|

Hydrogen flow rate |

0-500 mL/min |

|

Air flow rate |

0-1000 mL/min |

|

Dimensions (W × D × H) |

550 × 500 × 500 mm |

|

Weight |

39 kg |

|

Power supply |

from AC mains, voltage 230-240 V, frequency 50 Hz |

|

Maximum power consumption (isothermal mode) |

900 VA |

|

Technical compatibility of "NetChrom v 2.1" with other software |

LIMS I-LDS, STARLIMS |