Digital gas flow restrictor produced by PRC Meta-chrom is designed for designed to maintain a given pressure and the ratio of the amount of gases or gas flow rate in vacuum installations with automatic and manual control.

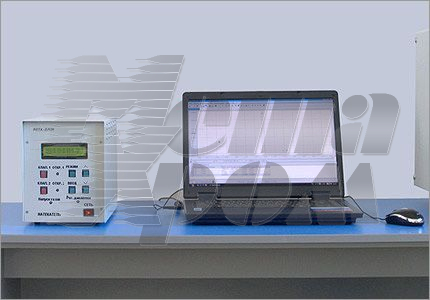

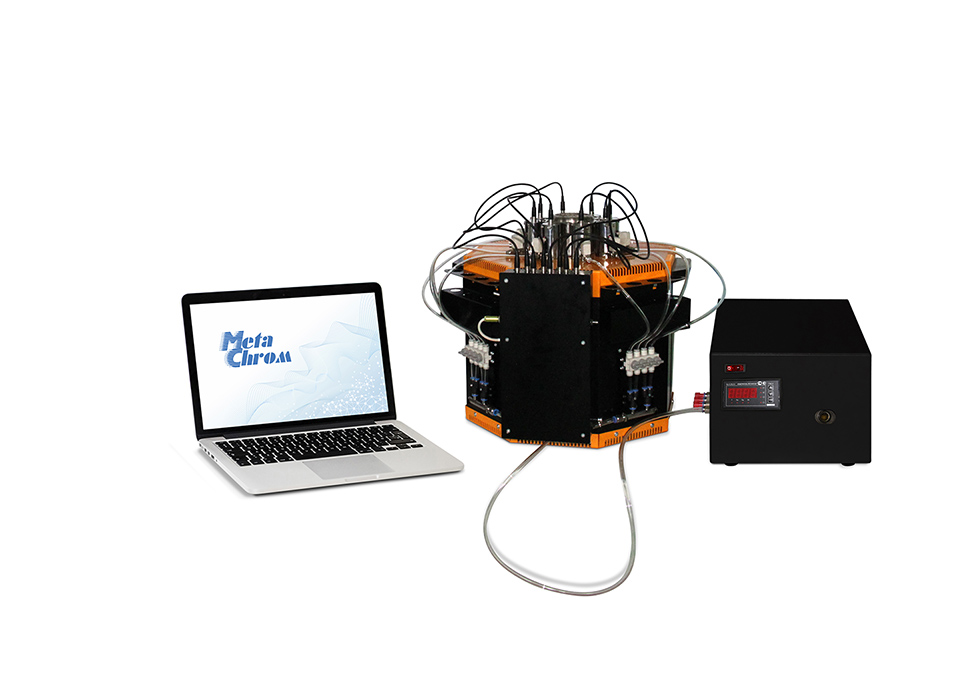

Photo:Digital gas flow restrictor

Unit control is performed either from keyboard of the unit or remotely from PC through interface RS-485.

Unit includes two or more (by preorder) in-built precise (sensitive) gas flow regulators with thermometric gauges of gas flow, and it allows the unit to work in the mode of autonomous inlet of the set gas flows, independent from inlet pressure. Leak valve has shut-off valves and control of inlet pressure on every channel. Leak valve has digital display for pressure control, gas flow control and setting of working parameters in manual mode from keyboard situated on the unit corpus.

Leak valve has two working modes:

- Maintenance of pressure in vacuum chamber and gas proportions.

- Maintenance of the set gas flows in two channels (in this mode leak valve works as gas flow generator).

Maintenance of pressure in vacuum chamber is done automatically in accordance with the set pressure value. Value of measured pressure comes through digital input from vacuum gauge (Meta-chrom or Barratron etc). There is possibility of smooth adjustment.

Value determined by thermocouple channel of vacuum gauge (highly inertial mode, close to static) or ionization (dynamic mode) may be used as measured pressure value.

There is possibility of quick adaptation for any volume of vacuum gauge by means of using proportional-integral-differential algorithm of (FID) regulator in program complex.

Following the competition “Best native measuring instrument-2008” “Digital leak valve of gases” unit was recognized as laureate and was awarded a corresponding dimloma.

Technical characteristics

- Number of regulation channels – 2 (or more by preorder.

- Maximum flow in each channel is 700 cm3/min.

- Possibility of using gas correction factors, mostly used gases are listed in database of leak valve.

- Precision of maintenance of the set gas proportions — 5 %.

- Precision of maintenance of the set gas flows — 3 %.

- Input pressures from from 1 to 4 atm.

- Electric power from single-phase network AC power with voltage from 187 to 242 V, frequency (50±1) Hz, work mode — continuous.

- Power consumption (without PC) no more than 30VA.

- Overall dimensions (width x depth x height) no more than 165x350x215 mm.

- Mass, no more than 5,5 kg.